Discover the Benefits of Silent Diesel Generators: A Practical Approach to Quiet and Reliable Power

Quiet Power, Clear Purpose: Introduction and Outline

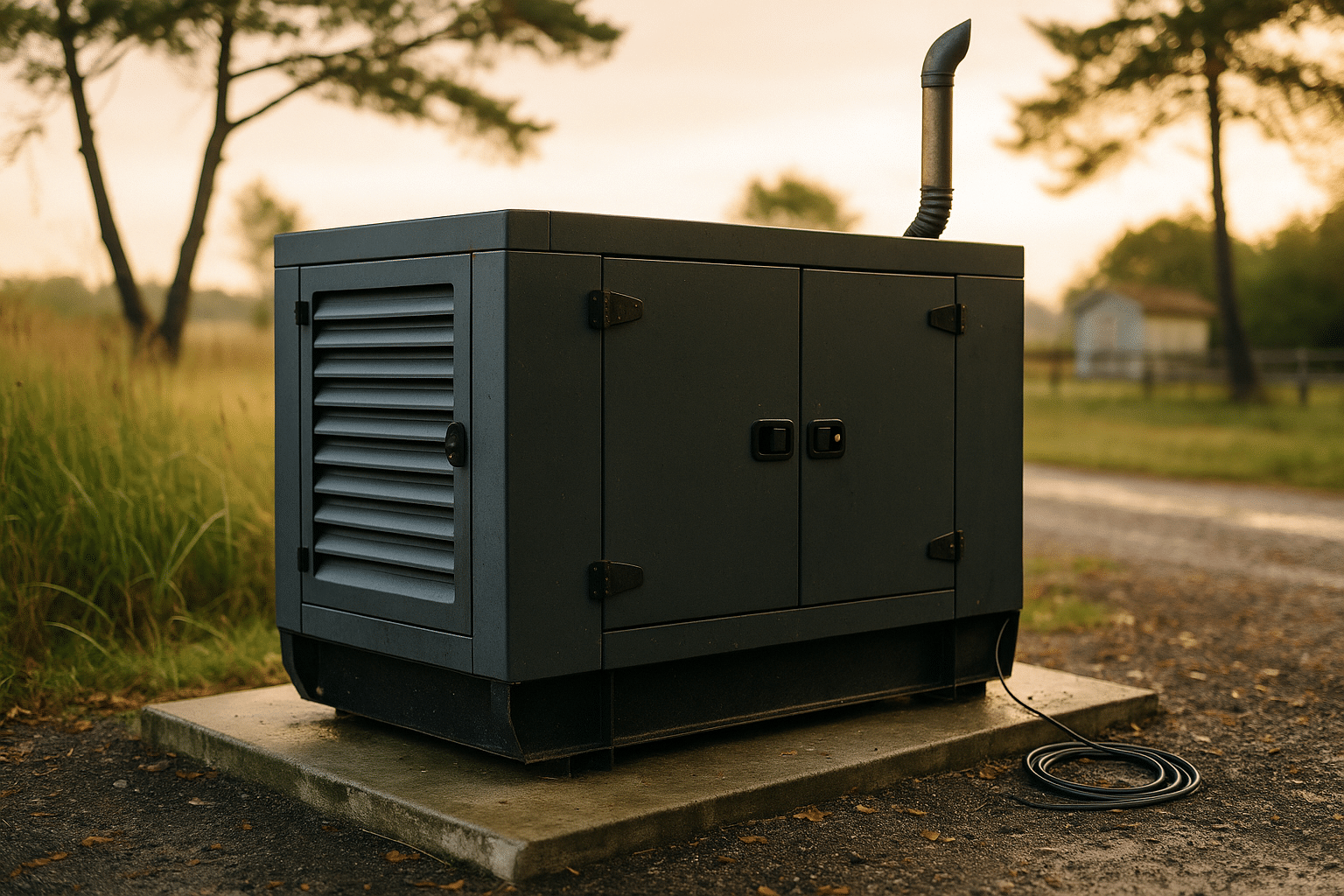

Reliable electricity underpins modern comfort and safety, yet outages still happen—storms knock lines down, construction sites sit beyond the grid, and remote clinics need assured uptime. Silent diesel generators step into these gaps with a valuable combination: robust engines, sound-attenuated enclosures, and steady frequency output that keeps sensitive equipment stable. While “silent” is a figure of speech, many models operate around 60–70 dB(A) at 7 meters, roughly comparable to a normal conversation or a quiet office. That difference can transform a backyard, event venue, or job site from intrusive noise to tolerable background hum, making power resilience easier to live with and work around.

In this article, we’ll move from first principles to field-ready decisions. Consider this the roadmap:

– How quiet design works: acoustic mass, damping, and airflow management in soundproof housings

– What performance numbers mean: kW vs kVA, fuel burn, load steps, and noise metrics

– Practical installation: siting, ventilation, exhaust routing, grounding, and transfer switching

– Compliance and care: emissions tiers, local ordinances, and safe fuel storage

– Ownership math: total cost of ownership, maintenance rhythms, and use-case examples

Noise matters for more than comfort. Long-term exposure above 70 dB(A) can contribute to annoyance and sleep disturbance, and many municipalities set nighttime limits in residential zones near 45–55 dB(A). Achieving these targets requires both engineering and planning: where the generator sits, how the exhaust points, and what barriers or landscaping support the enclosure’s built-in attenuation. Just as important, diesel’s efficiency and torque at low rpm make it well-suited to longer runtimes and heavier loads than many portable alternatives, reducing refuel cycles and offering stable frequency under transient demand. Think of a silent diesel unit as a compact power plant—contained, predictable, and courteous to its surroundings—when configured and operated thoughtfully.

Inside the Quiet: Acoustics, Enclosures, and Engine Technology

Quiet diesel performance is part physics, part airflow choreography. Soundproof enclosures rely on three pillars: mass to block airborne noise, damping to convert vibrations into heat at the panel level, and decoupling to break mechanical paths that let structure-borne vibrations escape. Panels often combine layers—powder-coated steel or aluminum skins, viscoelastic damping sheets, and acoustic foam—to address a broad frequency range from low engine rumble to higher fan and alternator tones. Gasketed doors, labyrinth intake and exhaust paths, and carefully sized baffles slow and absorb sound waves while preserving the volume of cooling air needed for the radiator and alternator.

The “silent” magic would fail without thermal management. Diesel engines need significant airflow, and so do alternators under sustained load. Engineers route air through S-shaped ducts lined with absorptive material; the geometry adds path length and reflection points, trading minor pressure drop for worthwhile attenuation. Meanwhile, the enclosure sits on vibration isolators that act like shock absorbers, interrupting the transfer of engine pulses to the slab or soil. This is why two generators with similar engines can sound very different—the enclosure design, air path, and mounts change the acoustic signature dramatically.

Under the hood, the engine’s operating speed sets the tone. Common fixed speeds are 1500 rpm for 50 Hz regions and 1800 rpm for 60 Hz, locking alternator frequency with minimal electronics. Modern fuel systems—high-pressure injection with precise timing—help lower specific fuel consumption and reduce combustion noise by improving atomization. Turbochargers enable compact engines to deliver strong torque, maintaining rpm during load steps that might otherwise cause a sag in frequency. On the emissions front, increasingly strict standards have pushed aftertreatment into even mid-size sets: diesel oxidation catalysts reduce carbon monoxide and hydrocarbons; particulate filters trap soot; selective catalytic reduction cuts NOx using urea injection. While these systems add complexity and maintenance steps, they also support cleaner operation and can slightly shift acoustic characteristics by smoothing exhaust pulses through larger-volume components.

What does this mean outdoors? A well-designed silent set can achieve approximately 60–70 dB(A) at 7 m in free field conditions, assuming correct installation. For context, a typical non-enclosed open-frame generator may exceed 80–90 dB(A) at similar distance. The difference is not a minor tweak; a 10 dB reduction is perceived roughly as halving loudness. That’s the audible payoff of mass, damping, and smart airflow working in concert with a steady, efficient diesel engine.

Performance and Sizing: Loads, Fuel Economy, and Noise Metrics

Matching a silent diesel generator to real-world loads starts with honest numbers. Electrical demand is frequently expressed in kilowatts (kW), while many generator nameplates use kilovolt-amperes (kVA). The relationship is kW = kVA × power factor, and most mixed loads hover around 0.8 power factor. Motors, compressors, and pumps need extra headroom: their inrush current can be 3–6 times running amperage for a second or two. If you size a generator to just the running watts, that startup surge may trip protection or cause the engine to bog down, upsetting sensitive electronics.

A practical sizing flow looks like this: list all loads, note which ones can run simultaneously, highlight motorized equipment, and decide whether to stage high-demand items or support them together. As a rule of thumb, a small, efficient residence might need 8–12 kW for essentials, while a construction trailer with HVAC, lighting, and tools might call for 20–40 kW. Upsizing slightly improves transient response and may reduce fuel stress, but extreme oversizing can lead to wet stacking—unburned fuel accumulating in the exhaust under chronically light loads. Load management panels and automatic sequencing help keep the generator in a comfortable utilization band, typically 40–80% of rated capacity for longevity and efficiency.

Fuel economy is another anchor. Modern diesel engines often achieve specific fuel consumption in the range of roughly 210–240 g/kWh under steady load. With diesel density near 0.84 kg/L, a 10 kW continuous load might consume around 2.5–2.9 L/h, depending on engine and alternator efficiency. Real consumption varies with load factor, ambient temperature, altitude, and aftertreatment. Silent enclosures introduce a minor fan power penalty, but the impact is modest compared to engine output. For longer runtimes, integrated day tanks and larger external tanks extend intervals between refills, and level sensors can trigger timely deliveries.

Noise metrics deserve clarity, too. Many spec sheets list LpA at 7 m (sound pressure level at a distance) under standard environmental conditions. Some also list LwA (sound power level), which is independent of distance and room effects. When comparing models, ensure the same test method and distance are used; otherwise, you’re comparing apples to oranges. A difference from 68 dB(A) to 64 dB(A) may sound small on paper but is noticeable in a quiet neighborhood at night, especially if reflective surfaces amplify sound. If you’re situating a unit near a wall, remember that reflections can add several dB; slight repositioning or a simple fence with absorptive panels can restore the intended “silent” experience.

Installation, Compliance, and Safety: From Placement to Soundproofing

The quietest generator can sound loud if installed poorly. Start with siting: keep clearances for service doors, allow straight-through airflow for the radiator path, and avoid corners that funnel noise toward nearby windows. A concrete pad or engineered compacted base distributes weight evenly and supports vibration isolators. Elevate slightly in flood-prone areas and consider a curb or spill containment to manage fuel and oil. Exhaust should terminate away from openings and above head height; horizontal runs should minimize backpressure, and rain caps or vertical stacks can reduce water ingress without relying on makeshift covers that rattle or whistle.

Ventilation and heat rejection matter year-round. In hot climates, shade from a simple canopy (set above the enclosure to preserve airflow) can lower inlet temperatures and improve performance. In cold regions, block heaters and battery maintainers keep cranking reliable and minimize white smoke on startup. Routing intake air away from dusty or salty sources protects filters and alternators; desert sites may need shorter service intervals for filters, while coastal installations benefit from anti-corrosion coatings and regular rinsing of external surfaces.

Compliance is local, so verify noise ordinances, fuel storage limits, and setback requirements. Many jurisdictions reference emissions tiers for off-road engines; ensure the chosen model meets current standards for your region. Electrical safety is non-negotiable: properly rated transfer switches—manual or automatic—separate generator power from the utility, preventing dangerous backfeed. Grounding and bonding must follow national codes, and neutral-ground configurations should match transfer equipment. For added acoustic control, simple site measures help: berms or timber fences with mineral wool infill, staggered with gaps for airflow; landscaping with dense shrubs; and turning the enclosure’s quiet side toward neighbors. These tactics can yield 3–6 dB additional reduction without compromising cooling.

Operational safety rounds it out. Keep extinguishers rated for fuel fires within reach, post clear shutdown and emergency procedures, and train anyone who might interact with the unit. Fuel tanks need proper vents, overfill protection, and labeling. Routine walk-arounds—checking for leaks, loose fasteners, and unusual vibrations—catch small issues before they grow. When the installation respects airflow, acoustics, and code, a silent diesel generator lives up to its promise: steady power that blends into the background.

Ownership Economics and Maintenance: Costs, Lifespan, and Real-World Scenarios

Total cost of ownership (TCO) blends purchase price, fuel, maintenance, and depreciation. Diesel sets often carry a higher upfront cost than smaller gasoline units, but their durability and fuel efficiency can balance the ledger over multi-year service. At steady loads, the per-kWh fuel cost is competitive, especially for extended runtimes where battery banks would need frequent recharging or significant upfront capacity. For periodic outages, a modestly sized silent unit paired with a transfer switch offers a pragmatic path: you avoid oversizing, curb fuel burn, and still cover vital loads.

Maintenance cadence is predictable: oil and filters typically every 250–500 hours depending on engine design and duty cycle; air filters inspected frequently in dusty environments; coolant flushes per manufacturer intervals; belts and hoses on condition. Batteries appreciate gentle treatment—float charging keeps them ready, and replacement every few years prevents no-start surprises. Exercise runs under load (monthly or per local guidance) circulate oil, dry out moisture, and confirm transfer switch function. Where light loading is common—think a well-insulated home with LED lighting—planned load bank tests help prevent wet stacking by bringing exhaust temperatures up, burning off deposits, and verifying full-load stability.

Comparisons add clarity:

– Versus gasoline: diesel offers lower fire risk due to higher flash point, better torque at low rpm, and typically longer engine life at constant speed; gasoline units are lighter and cheaper but noisier and thirstier per kWh under load.

– Versus liquid propane: propane burns clean and stores well; diesel is often more efficient per kWh and easier to refuel in remote areas with standard delivery.

– Versus battery-only: batteries shine for short outages and indoor silence; a silent diesel can provide days or weeks of power and recharge battery banks during long interruptions.

Real-world snapshots illustrate the trade-offs. A small clinic in a rural district pairs a 25 kW silent diesel with solar and batteries: daytime sun handles routine loads, while the generator covers cloudy stretches and critical equipment surges, keeping fuel use moderate. A construction site leans on a 40 kVA unit with scheduled quiet hours; placing the set behind a timber fence with absorptive panels keeps the evening decibels in check. An event organizer rents a 20 kW enclosed set, runs heavy cable to distribute power away from the stage, and schedules refueling during breaks—audiences hear the music, not the machinery.

Conclusion: Choosing Quiet Confidence

For homeowners, facility managers, and contractors, silent diesel generators offer a balanced blend of acoustic comfort, runtime, and resilience. Choose capacity with honest load lists, install with airflow and neighbors in mind, and commit to routine care. Do that, and your generator becomes the quiet colleague who shows up on time, carries the heavy boxes, and never demands the spotlight—power you can trust, without the noise you don’t want.