Material Handling and Packaging Guidelines

Introduction to Material Handling and Packaging

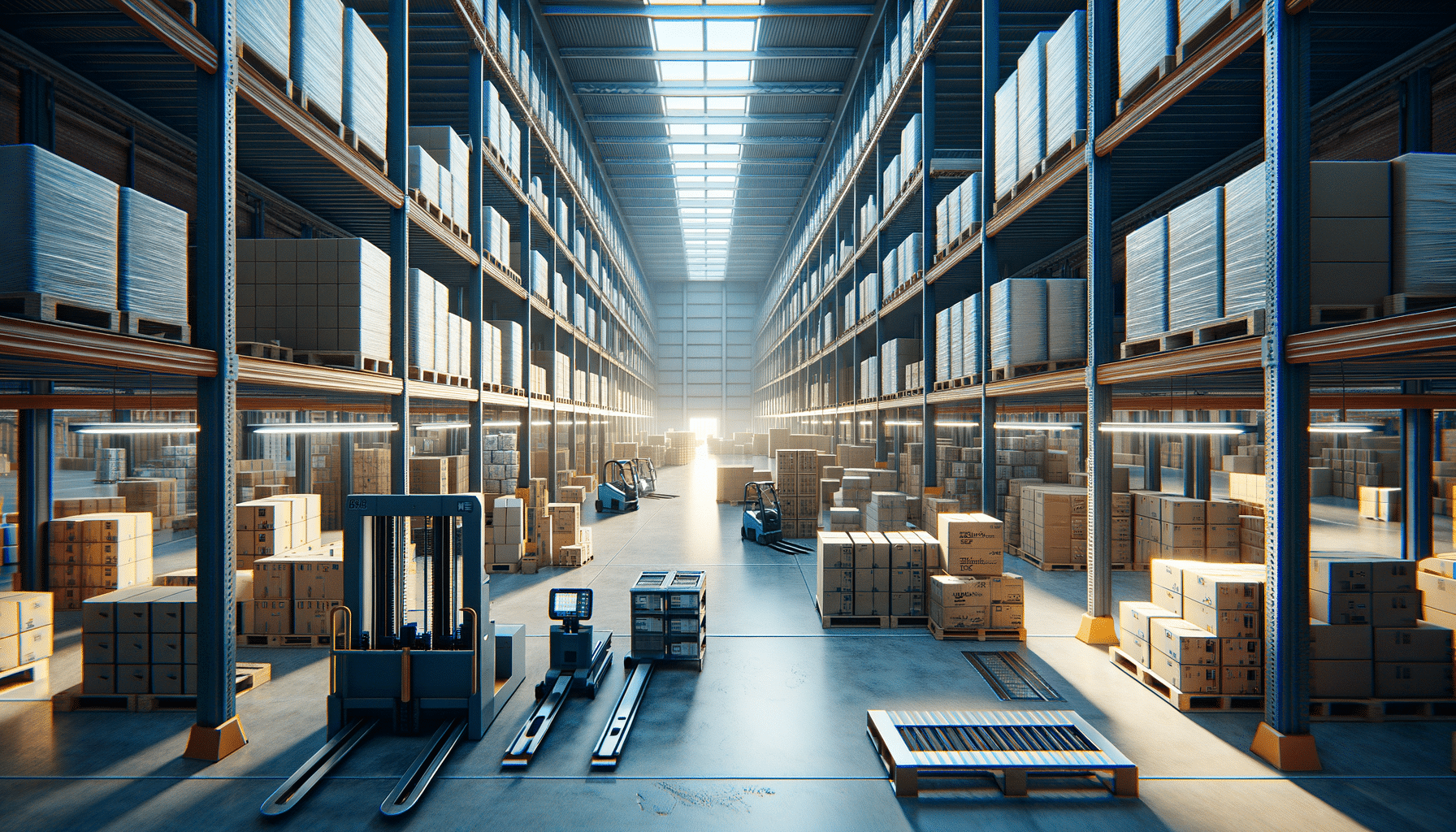

Material handling and packaging are pivotal in ensuring the efficiency and safety of supply chain management and industrial operations. These processes are integral to the movement, protection, storage, and control of materials and products throughout manufacturing, warehousing, distribution, consumption, and disposal. Effective material handling and packaging strategies can significantly reduce costs, improve safety, and enhance the overall productivity of operations.

In today’s competitive market, businesses are continually seeking ways to optimize these processes to meet the growing demands of consumers and to maintain a competitive edge. This article delves into the essential aspects of material handling and packaging, providing insights into their importance, types, and benefits.

The Importance of Material Handling

Material handling involves the short-distance movement of materials between two or more locations within a facility or at a site. It is a crucial component of manufacturing and logistics, impacting both the cost and efficiency of operations. Proper material handling reduces the risk of accidents, minimizes product damage, and ensures the smooth flow of materials across the supply chain.

Effective material handling can lead to:

- Reduced labor costs through automation and ergonomic design.

- Improved worker safety by minimizing manual handling and potential injury risks.

- Increased efficiency and productivity by streamlining the movement of goods.

- Enhanced inventory control and management by facilitating better tracking and organization.

By investing in advanced material handling equipment and technologies, companies can optimize their processes and achieve significant operational gains.

Packaging: Protecting and Preserving Products

Packaging plays a vital role in protecting products during transportation and storage. It ensures that goods reach their destination without damage, maintaining their quality and integrity. Packaging is not only about protection but also about preservation, branding, and providing essential information to consumers.

There are several types of packaging, each serving different purposes, including:

- Primary packaging, which directly contains the product.

- Secondary packaging, which groups primary packages for easier handling.

- Tertiary packaging, which is used for bulk handling, warehousing, and shipping.

Effective packaging can enhance product appeal, provide convenience, and reduce environmental impact through sustainable practices. Companies are increasingly adopting eco-friendly packaging solutions to meet consumer expectations and regulatory requirements.

Technological Advancements in Material Handling and Packaging

Technological advancements have revolutionized material handling and packaging, providing solutions that enhance efficiency and reduce costs. Automation, robotics, and data analytics are transforming these processes, offering numerous benefits such as increased precision, speed, and adaptability.

Key technological innovations include:

- Automated guided vehicles (AGVs) and robotic arms for precise material movement.

- Smart sensors and IoT devices for real-time tracking and monitoring.

- Advanced packaging machinery for faster and more efficient packaging processes.

These technologies enable businesses to optimize their operations, reduce human error, and improve overall productivity. As technology continues to evolve, the future of material handling and packaging promises even greater advancements and efficiencies.

Conclusion: The Future of Material Handling and Packaging

The future of material handling and packaging lies in the integration of advanced technologies and sustainable practices. As the demand for faster, safer, and more efficient processes grows, businesses must adapt to stay competitive. Embracing automation, data-driven decision-making, and eco-friendly solutions will be crucial in achieving operational excellence.

By focusing on these areas, companies can not only improve their bottom line but also contribute to a more sustainable and efficient supply chain. The ongoing evolution of material handling and packaging will continue to shape the industrial landscape, driving innovation and growth.