Laser Welding Machines: Advancements in Precision and Efficiency for Industrial Applications

Introduction to Laser Welding Machines

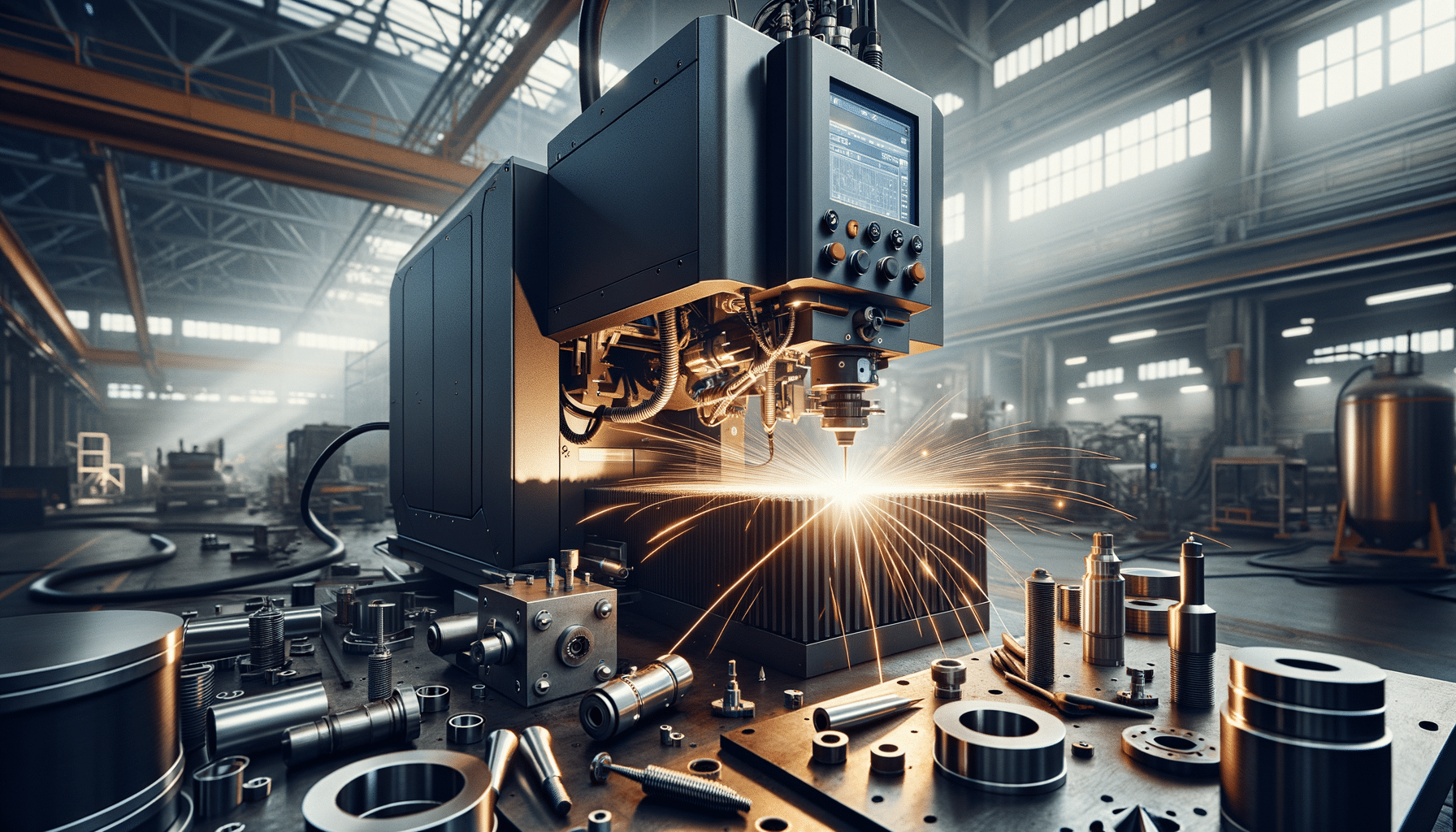

In the dynamic world of manufacturing, precision and efficiency are key drivers of success. Laser welding machines have emerged as pivotal tools in this landscape, offering unmatched accuracy and speed. These machines use high-powered lasers to join materials with precision, making them a staple in industries ranging from automotive to aerospace. As technological advancements continue to evolve, laser welding machines are becoming more accessible and versatile, making them a critical asset in modern manufacturing processes.

Advantages of Laser Welding Machines

Laser welding machines offer several advantages that make them a preferred choice for industrial applications. Firstly, they provide exceptional precision, which is crucial for industries that require tight tolerances. The ability to focus the laser beam with pinpoint accuracy ensures minimal distortion and high-quality welds. Additionally, laser welding is a non-contact process, meaning that the materials being welded are not subjected to mechanical stress, which can be beneficial for delicate components.

Another significant advantage is the speed of laser welding. Compared to traditional welding methods, laser welding can significantly reduce production times, leading to increased efficiency and output. This speed is particularly beneficial in high-volume production environments where time is of the essence. Furthermore, laser welding machines are highly adaptable, capable of welding a wide range of materials, including metals, plastics, and even dissimilar materials.

- Exceptional precision and minimal distortion

- Non-contact process reduces mechanical stress

- Increased efficiency with faster production times

- Versatility in welding various materials

Exploring Portable Laser Welding Machines

As industries seek more flexible solutions, portable laser welding machines have gained popularity. These compact units offer the same precision and efficiency as their larger counterparts but with the added benefit of mobility. Portable laser welding machines are ideal for on-site repairs and maintenance, making them invaluable for industries such as construction and shipbuilding.

The portability of these machines does not compromise their performance. They are equipped with advanced features that allow for easy setup and operation, making them user-friendly even for operators with limited experience. The ability to transport these machines to different locations without sacrificing quality makes them a cost-effective solution for businesses looking to expand their capabilities.

Pricing and Cost Considerations

Investing in laser welding machines requires careful consideration of costs. The initial purchase price can be significant, especially for high-end models with advanced features. However, the long-term benefits, such as increased efficiency, reduced labor costs, and improved product quality, often justify the investment.

When evaluating the cost of laser welding machines, it’s essential to consider the specific needs of your business. Factors such as the type of materials being welded, production volume, and required precision will influence the choice of machine. Additionally, maintenance and operational costs should be factored into the decision-making process to ensure a comprehensive understanding of the total cost of ownership.

- Initial investment vs. long-term benefits

- Cost influenced by material type and production volume

- Consideration of maintenance and operational costs

The Impact on Manufacturing Processes

Laser welding machines have significantly transformed manufacturing processes across various industries. Their ability to deliver precision and efficiency has led to improved product quality and reduced waste. In industries such as automotive, where safety and performance are paramount, laser welding ensures that components meet stringent standards.

Moreover, the adaptability of laser welding machines allows manufacturers to innovate and develop new products. The capability to weld complex geometries and dissimilar materials opens up new possibilities for design and engineering. As industries continue to evolve, the role of laser welding machines in driving innovation and competitiveness cannot be overstated.

Conclusion: Embracing the Future of Manufacturing

Laser welding machines represent a significant advancement in manufacturing technology, offering precision, speed, and versatility. As industries strive for greater efficiency and quality, these machines are becoming essential tools in the production process. Whether through stationary units or portable models, laser welding is reshaping the manufacturing landscape, enabling businesses to meet the demands of a competitive market while pushing the boundaries of innovation.