Laser Welding Machines: Advancements in Precision

Introduction to Laser Welding Machines

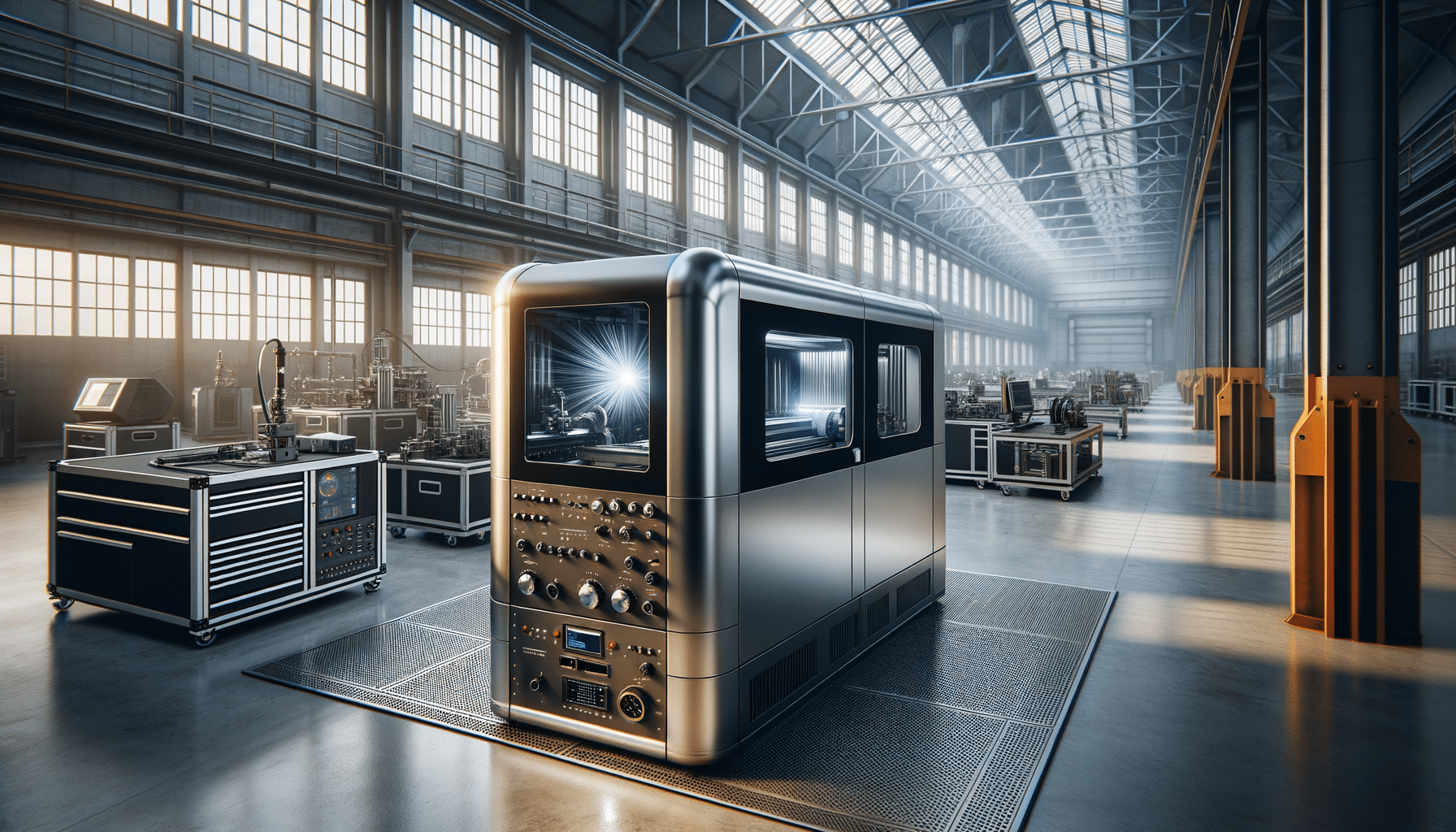

In the realm of modern manufacturing, precision and efficiency are paramount. Laser welding machines have emerged as a significant advancement in welding technology, offering unparalleled accuracy and speed. These machines utilize a focused laser beam to join materials, providing a clean and precise weld with minimal distortion. The relevance of laser welding machines in today’s manufacturing landscape cannot be overstated, as industries continually seek methods to enhance productivity while maintaining high-quality standards.

Laser welding machines are particularly beneficial in sectors where intricate and delicate components are prevalent, such as the automotive and aerospace industries. The ability to produce strong, precise welds without the need for extensive post-processing makes these machines a valuable asset. As we delve deeper into the world of laser welding, we’ll explore their advantages, the variety of models available, including portable options, and the factors influencing their pricing.

Advantages of Laser Welding Machines

Laser welding machines offer numerous advantages that make them a preferred choice in various industries. One of the most notable benefits is their ability to deliver high precision and accuracy. The focused laser beam allows for precise control over the welding process, resulting in clean and consistent welds. This precision is crucial in industries where even the slightest deviation can lead to significant issues.

Another advantage is the speed of the welding process. Laser welding is considerably faster than traditional methods, which can significantly reduce production times. This efficiency is particularly beneficial in high-volume manufacturing environments where time is a critical factor. Additionally, the non-contact nature of laser welding minimizes wear and tear on the equipment, leading to longer machine life and reduced maintenance costs.

Moreover, laser welding machines are known for their versatility. They can weld a wide range of materials, including metals, plastics, and even dissimilar materials. This flexibility allows manufacturers to use a single machine for multiple applications, further enhancing their value. Furthermore, the ability to automate the laser welding process can lead to increased productivity and consistency, making it an attractive option for industries looking to optimize their operations.

Portable Laser Welding Machines

With advancements in technology, portable laser welding machines have become increasingly popular. These models offer the same precision and efficiency as their larger counterparts but with the added benefit of mobility. Portable laser welding machines are ideal for applications where flexibility and ease of transport are essential.

One of the key features of portable laser welding machines is their compact design. Despite their smaller size, these machines are equipped with powerful lasers capable of delivering high-quality welds. This compactness makes them suitable for on-site repairs and installations, particularly in industries such as construction and shipbuilding, where access to stationary welding equipment may be limited.

Additionally, portable laser welding machines are user-friendly, often equipped with intuitive interfaces that simplify operation. This ease of use reduces the learning curve for operators, allowing for quicker integration into existing processes. The portability also means that these machines can be used in remote or hard-to-reach locations, providing a level of flexibility that traditional welding machines cannot match.

Pricing and Cost Considerations

The pricing of laser welding machines can vary significantly based on several factors, including the machine’s capabilities, size, and brand. Generally, laser welding machines are considered a significant investment, but their long-term benefits often justify the initial cost. Factors such as the power of the laser, the machine’s automation features, and its versatility in handling different materials can all influence the price.

It’s important for businesses to consider the total cost of ownership when evaluating laser welding machines. This includes not only the purchase price but also maintenance costs, energy consumption, and potential downtime. Machines with higher efficiency and lower maintenance requirements can offer better value over time, even if their upfront costs are higher.

Furthermore, businesses should assess their specific needs and production goals to determine the most cost-effective option. While more advanced machines with additional features may offer greater capabilities, they may not be necessary for all applications. Understanding the balance between cost and functionality is key to making an informed decision.

Impact on Manufacturing Processes

The introduction of laser welding machines has had a profound impact on manufacturing processes. Their precision and speed have revolutionized the way products are assembled, leading to improvements in both quality and efficiency. In industries such as automotive and electronics, where precision is paramount, laser welding has become an integral part of the production process.

Laser welding machines contribute to reduced production times and increased throughput, enabling manufacturers to meet the demands of a fast-paced market. The ability to automate the welding process further enhances productivity by minimizing human error and ensuring consistent results. This automation also allows for better resource allocation, as skilled labor can be redirected to other critical tasks.

Moreover, the quality of welds produced by laser machines often exceeds that of traditional methods, reducing the need for post-weld processing. This not only cuts down on production costs but also improves the overall durability and performance of the final product. As industries continue to evolve, the role of laser welding machines in shaping the future of manufacturing is set to expand, driven by the ongoing pursuit of excellence and efficiency.