Laser welding equipment: Advancements in Precision and Efficiency for Industrial Applications

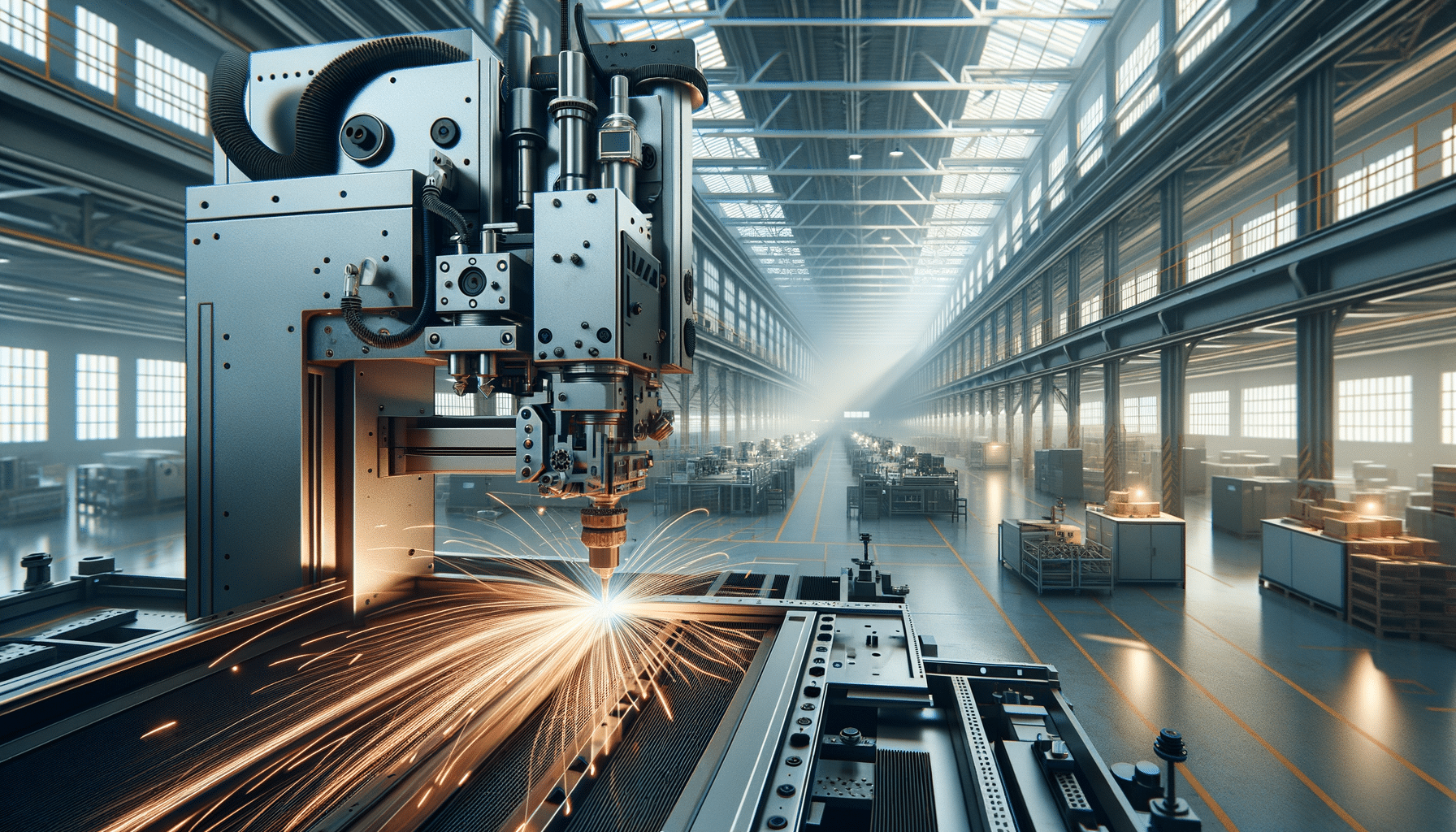

Introduction to Laser Welding Machines

Laser welding machines have become a cornerstone in modern manufacturing, offering precision and efficiency that traditional welding methods struggle to match. These machines utilize laser beams to fuse materials together, providing a high degree of control and accuracy. As industries continue to seek ways to improve production processes, the adoption of laser welding technology is increasing. In this article, we will explore the advantages of laser welding machines, delve into the specifics of portable models, examine pricing considerations, and assess their impact on manufacturing processes.

Advantages of Laser Welding Machines

One of the most significant advantages of laser welding machines is their ability to produce high-quality welds with minimal distortion. The precision of laser beams allows for targeted heating, reducing the heat-affected zone and preserving the integrity of the surrounding material. This precision is particularly beneficial in industries where component integrity is critical, such as aerospace and automotive manufacturing.

Additionally, laser welding machines offer faster welding speeds compared to traditional methods. This speed translates into increased productivity and reduced labor costs, making them a cost-effective solution for large-scale manufacturing. The non-contact nature of laser welding also minimizes wear and tear on the equipment, leading to lower maintenance costs.

- High precision with minimal distortion

- Increased productivity due to faster welding speeds

- Lower maintenance costs

Exploring Portable Laser Welding Models

Portable laser welding machines have revolutionized the industry by providing flexibility and convenience. These models are designed to be easily transported and set up, making them ideal for on-site repairs and maintenance tasks. Portable models retain the core advantages of stationary laser welders, such as precision and speed, while offering the added benefit of mobility.

The portability of these models allows for their use in diverse environments, from construction sites to remote locations, without sacrificing quality. This flexibility is crucial in industries like shipbuilding and pipeline construction, where components are often large and difficult to move.

- Flexibility and convenience for on-site repairs

- Maintains precision and speed of stationary models

- Ideal for diverse environments and remote locations

Pricing Considerations for Laser Welding Machines

The pricing of laser welding machines varies based on several factors, including power output, brand, and additional features. While initially more expensive than traditional welding equipment, the long-term benefits often justify the investment. High-quality laser welders can provide substantial savings through increased efficiency and reduced material waste.

When evaluating the cost of a laser welding machine, it’s essential to consider not just the initial purchase price but also the long-term operational costs. Factors such as energy consumption, maintenance, and potential downtime should be accounted for. Many manufacturers offer leasing options, making it easier for businesses to integrate laser technology into their operations without a significant upfront cost.

- Varies based on power output and features

- Long-term savings through efficiency and waste reduction

- Consider operational costs alongside purchase price

The Impact of Laser Welding on Manufacturing Processes

Laser welding machines have substantially impacted manufacturing processes by enhancing product quality and production efficiency. Their ability to produce precise, high-quality welds has led to improvements in product durability and performance. This technology also supports the trend towards automation, as laser welders can be integrated into robotic systems, facilitating seamless production lines.

Moreover, the reduced need for post-weld processing, such as grinding and polishing, further streamlines manufacturing operations. The adoption of laser welding technology not only boosts productivity but also encourages innovation by allowing manufacturers to explore new design possibilities that were previously constrained by traditional welding methods.

- Enhances product quality and production efficiency

- Supports automation and integration with robotic systems

- Encourages innovation in design possibilities

Conclusion

Laser welding machines represent a significant advancement in manufacturing technology, offering precision, efficiency, and flexibility. Whether through stationary units or portable models, their impact on manufacturing processes is profound, leading to improved quality and reduced costs. As the technology continues to evolve, it is poised to play an increasingly critical role in various industries, driving innovation and enhancing productivity. For businesses looking to stay competitive, investing in laser welding technology is a strategic move towards future-proofing their operations.