A Complete Guide to Buying and Installing a Home Container Swimming Pool

Outline and What Makes a Container Pool Appealing

Before diving into the details, here’s a quick outline of what you’ll learn and how to use it:

– Section 1: Big-picture overview, key advantages, and realistic limitations

– Section 2: Planning, permits, site selection, and backyard constraints

– Section 3: Cost breakdown, pricing examples, and budgeting strategies

– Section 4: Installation methods, foundations, plumbing, and electrics

– Section 5: Maintenance, safety, winterizing, and meaningful upgrades

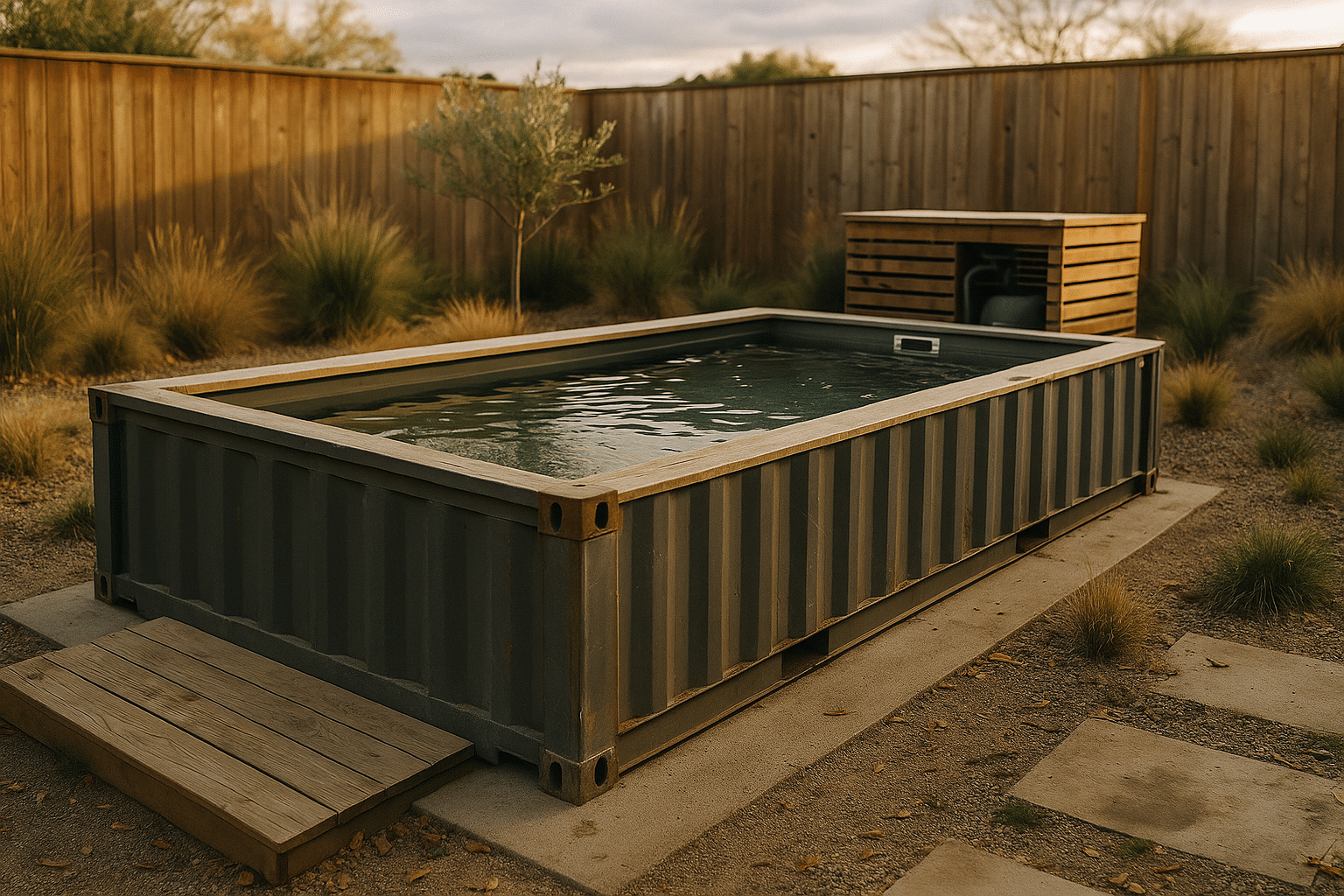

A shipping container pool repurposes an ISO steel container—often 20 or 40 feet long—into a watertight, engineered swimming vessel. It combines the sleek lines of modern design with the rugged character of corten steel, creating a backyard focal point that arrives largely pre-fabricated. For many homeowners, the draw is practical: a smaller water volume than most in-ground pools (roughly 4,000–5,000 gallons for a typical 20‑foot unit and around 8,000–10,000 gallons for a 40‑foot unit), quicker on-site installation, and the ability to place it in tight or sloped spaces where traditional shells struggle.

From a lifestyle lens, container pools offer swim lanes for exercise, a cool plunge spot for hot afternoons, and a conversation piece at gatherings. Their rectangular shape pairs well with simple decks, planters, and privacy screens, so even modest backyards can look curated without heavy landscaping. Pros often cite the speed: with the base prepared and utilities ready, placement and hookup can be measured in days rather than weeks. That said, the “plug-and-play” myth deserves a reality check. You’ll still need appropriate foundations, a safe electrical connection with ground-fault protection, a barrier fence or compliant cover, and—depending on local rules—a permit just like any other pool.

Compared with traditional options, container pools slot neatly between above-ground and custom in-ground builds. They are typically more affordable than a bespoke concrete design and may be comparable to or slightly more than a standard above-ground when you add decking and heat. Their constraints are clear, too: fixed widths (usually under 8 feet external) limit expansive shallow areas, depth is commonly around 4–5 feet of water, and structural modifications require careful engineering to preserve integrity. In short, they shine for homeowners who value straightforward lines, faster timelines, and controlled costs, while accepting a compact footprint and a pragmatic feature set.

Planning, Permits, and Site Selection

Good planning is the difference between a smooth install and a costly redo. Start by checking local codes for pool classification: some jurisdictions treat container pools as permanent structures, others as semi-permanent. Typical requirements include a barrier at least 4 feet high, self-closing and self-latching gates, anti-entrapment drain covers, and compliant electrical bonding. Expect plan review for setbacks from property lines, overhead power clearances, and proximity to septic systems or easements. In coastal or high-wind regions, anchoring or tie-downs may be requested to resist uplift and lateral forces.

Site selection comes next. Aim for a spot with sun exposure to help natural warming, easy access for a crane or telehandler, and convenient proximity to the electrical panel and water supply. Mind the ground: even a container pool needs a stable base. Many installs use a reinforced concrete slab, helical piles with steel beams, or compacted gravel with concrete piers. If frost is a factor, foundations should extend below frost depth or use frost-protected designs to avoid heave. Drainage matters as well; slope the site so stormwater moves away from the pool, and consider perimeter drains or a simple French drain where runoff collects.

Think through utilities with a practical lens:

– Electrical: A dedicated circuit, ground-fault protection, proper bonding, and exterior-rated conduit are standard expectations.

– Plumbing: Keep equipment close to reduce head loss; thoughtful placement of skimmer(s), returns, and suction lines improves circulation and reduces “dead spots.”

– Gas or heat pump lines: If heating is planned, confirm distances and ventilation clearances; for heat pumps, ensure unblocked airflow.

Finally, plan for people. Will the entry be ladder, steps, or a side cutout with a platform? Where will towels hang and gear live? Can you integrate shade and sightlines for supervision? A container pool rewards minimalism, but comfort features like a slim deck, a shaded bench, and a low-glare path light (installed to code and away from the water) elevate daily use. Document your plan with a simple sketch: show boundaries, setbacks, foundations, utilities, and equipment pad. That drawing pays for itself when you submit for permits and coordinate contractors.

Cost Breakdown, Pricing Examples, and Budget Tips

Costs vary by region, size, and finish level, but predictable patterns emerge. A 20‑foot container pool unit with internal waterproofing, skimmer, return lines, pump, filter, and basic lighting often lands in the range of $20,000–$45,000. A 40‑foot model with swim window or lap-friendly features can reach $35,000–$80,000, especially if you add integrated benches, insulation, or a prefabricated equipment bay. Site work adds more: a reinforced slab or set of piers ($1,500–$6,000), excavation or grading ($800–$3,500), crane access ($500–$2,500), electrical connection and bonding ($1,000–$4,000), and any necessary gas line for heating ($800–$2,500). Decking and landscaping swing widely—simple platforms start around $2,000–$5,000; expansive hardwood or composite builds can exceed $10,000.

Heating and water treatment choices shape both upfront and ongoing costs. Air-source heat pumps are widely used for efficiency; typical units draw roughly 1.5–3.5 kW under load and can keep a 20‑foot pool comfortable in shoulder seasons depending on climate. Gas heaters warm water faster but consume more fuel per degree rise; solar mats add low-operating-cost heat if you have roof or yard space. Chemical treatment remains straightforward: many owners spend $20–$60 per month on sanitizers and pH control, plus optional algaecide and clarifier. Electricity for pumps and lights ranges with schedules and regional rates; budget roughly $25–$75 per month in mild climates and more where heaters run often.

To visualize, consider three simplified scenarios:

– Compact functional: 20‑foot unit, gravel base with concrete piers, small equipment pad, no heater, basic deck. Rough total: $25,000–$38,000.

– Family-friendly: 20‑foot unit with heat pump, mid-size deck with steps and privacy screen, upgraded interior coating, safety cover. Rough total: $38,000–$58,000.

– Lap-oriented: 40‑foot unit, reinforced slab, heat pump plus solar assist, longer deck with storage, glass end or window feature. Rough total: $55,000–$95,000.

Where to save without cutting safety:

– Keep the equipment close to the pool to reduce trenching and hydraulic losses.

– Choose a modest deck now with footings positioned for future expansion.

– Use off-peak pump schedules and a solar cover to trim energy use.

– Insulate the pool interior or equipment lines in cooler climates to reduce heat loss.

Where to spend for long-term value:

– Quality waterproofing and corrosion protection (coatings, proper prep, and attention to edges/welds).

– A reliable safety cover or compliant fence; it helps with both safety and heat retention.

– Automation for basic scheduling and remote checks, which can reduce chemical swings and service visits.

Installation Methods and Technical Details

While container pools arrive largely assembled, the groundwork determines performance. Begin with the base. A monolithic concrete slab (often 4–6 inches thick with reinforcing and thickened edges) offers uniform support and helps with leveling. In many backyards, helical piles with steel beams or concrete piers are attractive because they minimize excavation and allow air circulation under the steel, which reduces corrosion risk from trapped moisture. Compacted gravel (well-graded, compacted in lifts) under piers can improve drainage and frost resistance. Verify elevations—container pools must sit level end-to-end and side-to-side to avoid unsightly waterlines.

Waterproofing and corrosion control deserve special attention. Although containers are made from weathering steel, pool duty introduces continuous wetting, chlorides, and potential galvanic coupling with dissimilar metals. Robust surface preparation (blast or grind to sound metal), a multi-coat barrier system (often epoxy or polyurea), and careful detailing at corners and welds are common practices. Some builds add a fiberglass lining or a drop-in shell for additional security. Penetrations for skimmers, returns, and lights should be sealed with compatible gaskets and flanges; fasteners must match the system to avoid galvanic corrosion. Where feasible, isolating the shell from constant ground moisture using air gaps or membranes helps longevity.

Plumbing is straightforward but benefits from thoughtful layout. Keep suction and return lines balanced to promote even circulation; avoid sharp bends and long runs. Many owners choose a single skimmer and two returns on a 20‑foot model, scaling up for a 40‑foot layout. Include a vacuum port or ensure the skimmer can accept a vacuum plate for manual cleaning. Equipment typically includes a variable-speed pump, cartridge or sand filter, optional heater, and an inline chlorination or salt chlorine generation system. Valves for bypassing the heater and isolating components simplify service.

Electrical work, by code, requires a licensed professional. Expect a dedicated circuit sized for the pump and any heater, outdoor-rated disconnects, ground-fault protection, bonding of metal parts within specified distances, and equipotential bonding near the water. Low-voltage lighting is common for safety and ambiance; confirm ingress protection ratings and follow required setbacks.

Logistics complete the picture. Many containers are craned over a house or placed from the street; plan access widths, overhead clearance, and staging areas. A dry run—measuring turning radii, removing a section of fence, or temporarily relocating shrubs—often prevents day-of surprises. After placement, the sequence is: connect plumbing and electrics, pressure-test lines, fill gradually while checking for weeps, balance water chemistry, and commission equipment. With a crisp foundation and coordinated trades, on-site work can wrap in a few days; more complex decks or hardscapes will extend the timeline.

Maintenance, Safety, and Smart Upgrades

Container pools are compact, which simplifies many tasks, but consistency is still key. Test water 2–3 times per week in season; maintain sanitizer within the recommended range, keep pH around 7.2–7.8, and watch alkalinity and calcium hardness to protect coatings and equipment. Clean the filter per manufacturer guidance; cartridge filters rinse quickly with a hose, while sand filters benefit from periodic backwash. A weekly brush and a few minutes with a leaf net keep surfaces pristine and reduce the load on chemicals. If you use a salt system, monitor salt levels and cell condition—scale buildup reduces efficiency. In cooler climates, winterizing involves lowering water below skimmers (if required), blowing out lines, adding winter chemicals, and securing a safety cover; in milder regions, reduced pump schedules and a leaf cover may be sufficient.

Safety is both code compliance and common sense. Provide a compliant barrier or a certified safety cover; a lockable roller cover adds daily peace of mind and heat retention. Non-slip entry steps, a sturdy handhold, and clearly visible depth indicators help guests. Check that all drains are anti-entrapment rated and that suction outlets are balanced or protected by vac-release systems where required. Electrical safety matters year-round: keep outlets and fixtures at proper distances, maintain ground-fault protection, and schedule periodic inspections.

Upgrades can enhance comfort without inflating workload:

– A heat pump paired with a solar cover extends shoulder-season use with modest energy draw.

– Simple automation handles pump speeds, chlorination, and lighting schedules, trimming waste and stabilizing chemistry.

– Interior insulation panels reduce heat loss and, in some designs, dampen drumming sounds from rain or splashing.

– A slimline deck with storage hides hoses, test kits, and toys while improving access for cleaning.

How do container pools compare long-term? Against a large concrete build, they typically use less water and fewer chemicals due to smaller volume. Against above-ground pools, they provide a more architectural look, stronger structural shell, and easier integration with modern decks and privacy screens. Expect liner or coating maintenance over time—interior finishes can last years when chemistry is kept in balance and surfaces are brushed. Periodic inspection of welds, edges, and fasteners helps catch small issues before they grow.

Finally, consider environmental impact. Repurposing steel reduces demand for new shell materials, and the compact footprint limits excavation. Responsible choices—variable-speed pumps, solar covers, and smart schedules—can trim energy use noticeably. Keep expectations grounded: a container pool rewards steady care and thoughtful upgrades, delivering years of reliable, refreshing use in a tidy, contemporary package.