Addressing Energy Demand: Solar Panels as an Option

Outline

To help you evaluate solar panels as a response to rising energy demand, this article follows a clear path. We start with how solar technology converts sunlight into electricity and what that means for real-world performance. From there, we examine costs, incentives, and payback factors using practical numbers. Next, we look at siting and design decisions that shape output, safety, and longevity. We then connect reliability, maintenance, grid integration, and environmental footprint to the user experience. Finally, we conclude with a decision guide that ties the analysis back to your goals, usage patterns, and budget.

The structure at a glance includes these themes you can skim or study in depth:

– Fundamentals of photovoltaic conversion and system components

– Cost drivers, financing, and how payback is calculated

– Site assessment, shading, orientation, and sizing

– Reliability, operations, interconnection, and sustainability

– A conclusion focused on choosing an option aligned with your needs

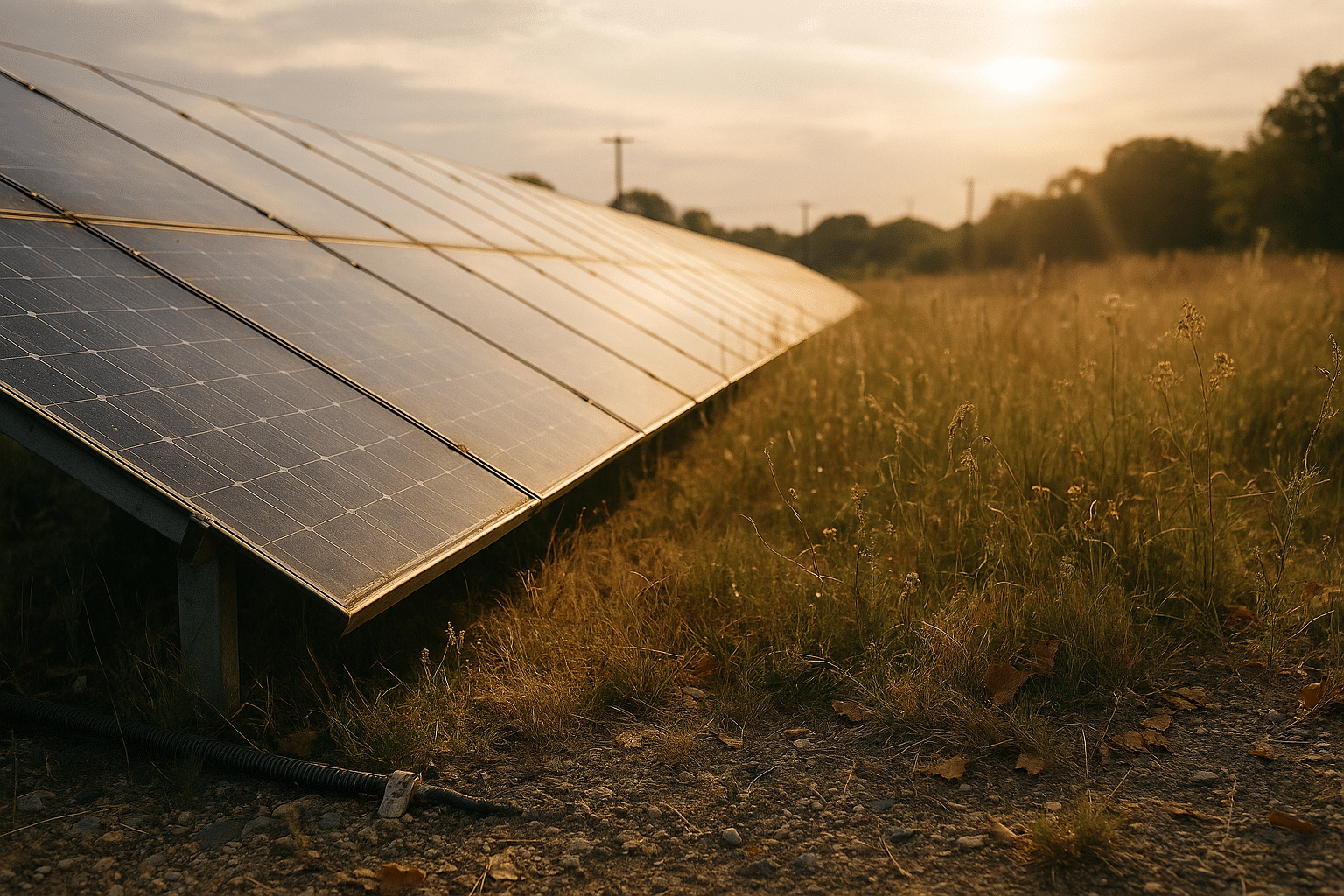

How Solar Panels Turn Sunlight into Usable Power

At its heart, a solar panel is a semiconductor device that converts light into direct current via the photovoltaic effect. When photons strike a solar cell, they free electrons that are guided by an internal electric field to produce current. A panel is a series of cells laminated under tempered glass, framed by aluminum, and wired to deliver a specific voltage and current. Most residential arrays are built from crystalline silicon modules, with typical nameplate efficiencies between about 18 and 22 percent. Thin-film modules exist as well, trading lower efficiency for lightweight, flexible form factors that suit certain rooftops and structures.

Panels do not work alone; an inverter translates the panel’s direct current into alternating current compatible with household circuits and the grid. Three inverter architectures are common. A string inverter ties many panels together in a series; it’s straightforward and cost-efficient, but one shaded panel can influence the whole string. Module-level electronics, such as microinverters or power optimizers, allow each panel to operate closer to its own maximum power point, reducing the impact of partial shading and mismatch. Hybrid inverters add the ability to manage batteries and support backup circuits during outages.

Real-world production depends on irradiance, temperature, angle, and losses across the system. Panels are rated at standard test conditions of 1,000 watts per square meter and 25°C cell temperature, which differ from a roof on a hot afternoon or a winter morning. Heat raises cell resistance and reduces efficiency, while cooler, bright days can boost output. Mechanical and electrical losses—soiling, wiring resistance, inverter conversion, and module mismatch—typically absorb 10 to 20 percent of potential generation over a year. A practical way to frame expectations is the capacity factor, the ratio of actual output to the theoretical maximum if the system ran at its rating all the time. For rooftop solar, capacity factors often fall in the 12 to 22 percent range depending on location and design.

These physics and system choices explain why two identically sized arrays can behave differently. A south-facing roof with limited shade and good airflow will outperform an east-west array under trees, even if both are 6 kilowatts. Properly balancing module type, inverter strategy, conductor sizing, and mounting airflow can close much of the gap between a brochure number and day-to-day kWh on your meter.

Costs, Payback, and Incentives: What the Numbers Say

Residential solar prices are commonly quoted per watt of direct current capacity. Installed costs frequently range from roughly 2 to 4 dollars per watt before incentives, influenced by roof complexity, permitting, labor rates, and component selection. A 6 kW system might therefore appear between 12,000 and 24,000 dollars before any credits or rebates. Commercial projects tend to achieve lower per-watt costs because of scale and simpler mounting surfaces, while small, intricate rooftops lean higher. Financing can reshape cash flow: loans spread out payments but add interest; leases and power purchase agreements may limit upfront expense in exchange for long-term obligations.

Public policies matter. Many regions offer tax credits, accelerated depreciation for businesses, performance-based incentives, or one-time rebates. Net energy metering or similar crediting rules determine how exported kilowatt-hours are valued, which can swing payback timelines by years. Where exports earn close to retail rates, daytime solar production offsets nighttime usage via credits. Where rates are lower for exports, self-consumption strategies—load shifting with timers, pre-cooling, or pairing with batteries—gain importance.

A simple payback estimate starts with annual generation. Suppose a 6 kW system produces 9,000 kWh each year and your blended electricity rate is 0.20 dollars per kWh. That offsets about 1,800 dollars annually. If the net cost after incentives is 14,000 dollars, the simple payback lands near 7.8 years. Actual outcomes vary: electricity rates may rise faster than inflation, shifting the economics, and maintenance or inverter replacement costs should be budgeted over decades. Levelized cost of energy, which spreads all costs over lifetime production, can frame comparisons to utility rates. For many rooftops, residential solar’s lifetime cost can fall within roughly 0.08 to 0.18 dollars per kWh, depending on sunlight, policy, and financing assumptions.

Key factors that tilt the math include:

– Sunlight resource and roof orientation

– Export credit rules and time-of-use pricing

– Upfront incentives and tax treatment

– Financing terms and interest rates

– Expected equipment lifetime and degradation profiles

Because nothing about energy bills is static, sensitivity testing is helpful. Examine scenarios with higher and lower utility rates, varying export compensation, and a modest panel degradation rate of around 0.3 to 0.8 percent per year. A plan that still pencils out under conservative assumptions is more likely to meet your expectations when weather, rates, and behavior inevitably shift.

Site Assessment and System Design: Roofs, Angles, and Shading

Good solar design starts with a careful look at the roof or ground space. Orientation and tilt shape daily production curves. In the northern hemisphere, south-facing surfaces capture more midday sun, while east and west orientations spread generation toward morning and late afternoon. Fixed-tilt arrays often aim for a tilt near the site’s latitude, but many rooftops dictate angles, and the differences across reasonable tilts are not dealbreakers. What matters as much is shading. Even narrow shadows from chimneys, vent stacks, or a neighbor’s tree can pinch output on certain strings or hours.

Before finalizing a layout, evaluate these elements:

– Structural condition of the roof deck and rafters

– Roof age, material, and remaining life before re-roofing

– Shading patterns across seasons and times of day

– Setbacks required by local fire and building codes

– Wind exposure, snow loads, and corrosion risks

System sizing should trace back to your actual consumption. Recent electric bills reveal your annual kWh use and peek demand patterns. A household that uses 9,000 kWh may target a system producing a similar annual total, but local policies and export compensation can justify slightly smaller or larger arrays. If export credits are low, right-sizing to meet daytime loads can improve economics. Consider flexible circuits: electrification of vehicles, water heating, or space conditioning can shift demand into sunlit hours, increasing self-consumption and improving returns.

Panel layout is part performance, part craft. Aim for even strings, short wire runs, and adequate ventilation under modules to reduce heat buildup. Module-level power electronics can mitigate partial shading and complex roof geometries. Conductor sizing reduces resistive losses; well-placed combiner boxes and clear conduit paths simplify maintenance. Ground mounts require attention to anchoring and soil conditions, and they typically allow ideal tilt and azimuth at the cost of using yard space.

Finally, design for safety and serviceability. Clear roof pathways for firefighters, labeled shutoff points, and rapid shutdown capabilities are now common requirements. Keep gutters, skylights, and drainage paths unobstructed. Plan for access to inverters and monitoring equipment, and keep spare parts documentation handy. A tidy, code-compliant installation earns approvals faster and makes the next twenty-five years smoother for everyone who touches the system.

Reliability, Maintenance, Grid Integration, and Environmental Footprint

Modern solar arrays are designed to operate for decades, and their reliability hinges on a handful of variables: component quality, weather exposure, and installation detail. Most panels carry performance warranties around 25 years, guaranteeing a percentage of the original output after that time. Typical degradation rates fall between about 0.3 and 0.8 percent per year. Inverters do more work and may need replacement once or twice over a system’s life, often after 10 to 15 years for certain models. Connections, flashing, and racking hardware must endure heat cycles, wind uplift, and moisture; careful sealing and stainless or coated fasteners help resist corrosion.

Routine care is modest for many sites. Rain rinses dust in numerous climates, but dry regions or pollen seasons can benefit from occasional cleaning with soft water and non-abrasive methods. Visual inspections once or twice a year can catch loose clamps, damaged wires, or hotspots identifiable via monitoring data. Keep vegetation trimmed beneath ground mounts and clear debris that could trap moisture or create shading. Many owners monitor hourly or daily production through web dashboards, which are useful for spotting inverter faults or a sudden dip that hints at shading from a newly grown branch.

Grid integration is evolving quickly. Smart inverters support voltage and frequency ride-through, volt-var control, and remote updates that help stabilize neighborhood circuits with growing distributed generation. Interconnection agreements define export limits and any required protective devices. Where the grid is constrained, utilities may encourage midday self-consumption or storage pairing to shape exports. Batteries allow time-shifting of solar energy to evening peaks and support limited backup; hybrids can maintain selected circuits during outages while keeping utility workers safe through automatic islanding protocols.

On environmental footprint, several lifecycle studies converge on comparatively low greenhouse gas emissions for solar electricity. When manufacturing, transport, installation, and end-of-life handling are included, rooftop solar often lands in a range on the order of a few tens of grams of CO2-equivalent per kWh, far below typical combustion-based generation. Land use is minimized on rooftops, while ground mounts should consider biodiversity, soil health, and dual-use practices such as pollinator-friendly plantings. End-of-life planning is gaining traction; glass, aluminum frames, and some semiconductor materials can be recovered, and emerging recycling programs are expanding as volumes grow. Thoughtful procurement—seeking transparent supply chains and certifications where available—can further reduce embedded impacts.

Maintenance checklist highlights:

– Inspect mounting points and conduit seals annually

– Review monitoring data for persistent underperformance

– Clean modules only when needed and with gentle methods

– Prune vegetation to avoid seasonal shading

– Document serial numbers, warranties, and system topology for quick troubleshooting

Conclusion: Matching Solar to Your Energy Demand

Choosing solar is less about chasing a trend and more about aligning technology with your energy profile. Begin with your annual kWh usage, roof orientation, and local policies; those three inputs drive most outcomes. If your site enjoys strong sun and fair export crediting, a grid-tied array can trim bills steadily and shorten payback. Where export rates are modest, plan for self-consumption by shifting loads or pairing a right-sized battery to move daytime generation into evening peaks. Businesses may layer in tax treatments and demand charges, which shift the optimization toward daytime consumption and targeted peak shaving.

To make a confident decision, walk through a simple framework:

– Define goals: bill savings, backup capability, emissions reduction, or a blend

– Gather data: twelve months of bills, roof details, and any planned electrification

– Model scenarios: different array sizes, financing options, and export rules

– Stress-test assumptions: higher rates, lower sun, and realistic degradation

– Plan for service: inverter replacement budgets and routine checks

Solar panels are a practical tool, not a magic wand. When sited sensibly and financed prudently, they can shoulder a meaningful share of your demand while reducing exposure to price spikes and outages. When conditions are less favorable—heavy shading, complex roofs, or restrictive interconnection—efficiency upgrades or community-scale projects may offer more value. Either way, an informed approach pays dividends. Start with a site assessment, compare a few designs, and let the numbers guide you. If the fit is right, sunlight becomes one of the most dependable contributors to your long-term energy plan.