Affordable Laser Welding Machines: A Practical Guide for Buyers

Introduction and Outline: Why Affordable Laser Welding Matters Now

Laser welding has moved from elite factory floors into everyday fabrication shops, repair bays, and small manufacturing startups. Falling component costs and maturing fiber sources have nudged prices down while performance keeps climbing. For buyers, that shift creates a clear opportunity: a precise, clean, and fast joining process at a price point that no longer requires an enterprise-sized budget. But affordability only pays off when you understand what you’re buying, how to deploy it, and how to keep it humming without hidden costs. This guide aims to demystify those choices so you can compare, calculate, and buy with confidence.

At its core, laser welding focuses energy into a tiny spot to melt metal with minimal distortion and a narrow heat-affected zone. That can translate into neat seams, reduced post-processing, and high travel speeds on thin and mid-gauge materials. Compared with conventional processes, you’ll often see dramatically less rework, fewer jigs, and less heat tint on stainless. Yet not every job favors a laser, and not every “deal” is truly economical once you factor in power, gas, consumables, and training. The right purchase balances specification, safety, and total cost of ownership with the real work your shop performs.

What this guide covers at a glance:

– The fundamentals: how laser welding works, key machine types, and common use cases

– Cost and value: price tiers, operating expenses, and sample ROI math

– Materials and quality: thickness ranges, joint types, and defect prevention

– Buying checklist: features that matter, safety and compliance, and integration tips

– A pragmatic conclusion: matching machine to workflow without overspending

Think of this as a field manual, not a brochure. You’ll find realistic ranges, plain-language explanations, and practical heuristics to pressure-test your shortlist. Whether you’re outfitting a small fabrication bench or planning a compact production cell, the sections below will help you separate must-have capabilities from shiny distractions, and spot the sweet spot where performance meets price.

How Laser Welding Works: Types, Power, and Practical Capabilities

Laser welding relies on a focused beam—most commonly a fiber source around 1070 nm—to deliver high power density at a small spot. That intensity can produce conduction-mode welds (shallow, smooth) or keyhole-mode welds (deeper penetration with a narrow profile). Continuous-wave systems excel at steady travel on thin to mid-gauge metals, while pulsed systems can help control heat input, reduce distortion on delicate parts, or tackle reflective materials with higher peak power.

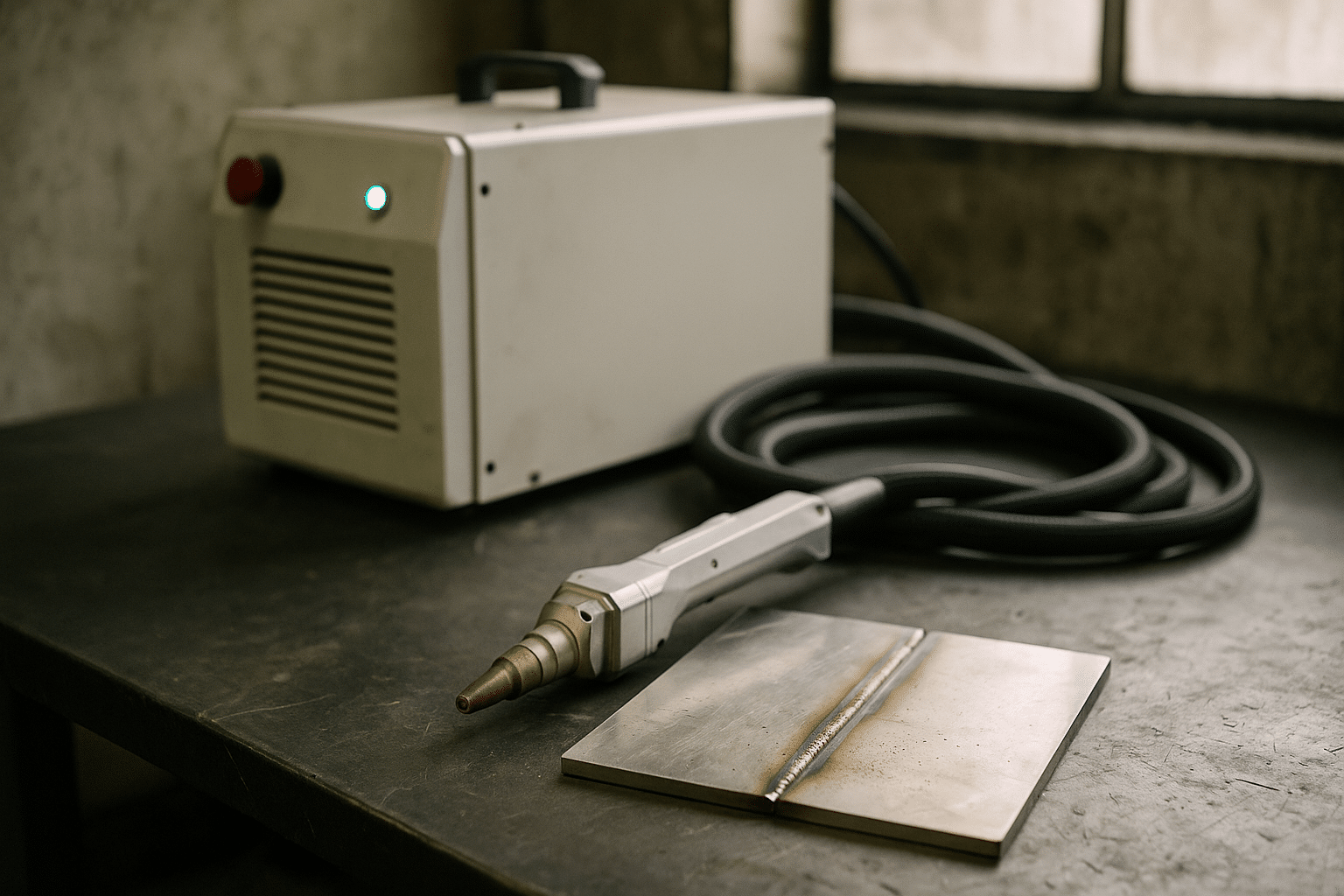

Common machine formats include handheld units with a gun-style head, benchtop stations with fixtures for repeatable small parts, and robotic cells for high-throughput, multi-axis jobs. For buyers seeking affordability, handheld fiber units in the 1–2 kW range have become especially attractive: they’re compact, fast to deploy, and suitable for stainless, carbon steel, and aluminum within appropriate thickness windows. Typical travel speeds on 1 mm stainless can reach 1–2 m/min with good fit-up, climbing higher on thin sheet and slowing on thicker sections.

Key technical considerations:

– Power and duty cycle: Handheld units often run 1–2 kW; automated cells may use 3–6 kW for deeper penetration.

– Spot size and beam quality: Smaller spots raise intensity, but joint fit-up and joint design must support it.

– Motion control: “Wobble” patterns (small circular or figure-eight motions) widen the seam and help bridge modest gaps.

– Shielding gas: Argon or nitrogen at roughly 10–20 L/min is common; gas choice affects bead appearance and porosity risk.

– Wire feed: Optional filler wire can help gap bridging and profile shaping, especially on fillets or poor fit-up.

Practical capability ranges depend on power, optics, and joint design. As a rough guide, 1.5–2 kW handheld units can handle stainless and mild steel in the 0.5–4 mm bracket with suitable prep; aluminum typically prefers the higher end of that power and meticulous cleaning to avoid porosity. Copper and brass present reflectivity challenges; solutions include higher peak power, careful surface prep, or process development to mitigate spatter and instability. Seam widths often land around 0.2–1.0 mm, with heat tint and distortion substantially lower than many conventional processes when parameters are dialed in.

Where lasers truly shine is precision and repeatability. A stable process can cut post-weld grinding dramatically and reduce fixturing complexity. On the other hand, tight fit-up and consistent joint geometry matter more than with filler-heavy processes. If your workload includes varied gaps, misaligned parts, or contaminated surfaces, plan for wire feed, wobble capability, better fixturing, or a quick upstream improvement in part prep to unlock the machine’s potential.

Cost and Value: Pricing Tiers, Operating Expenses, and ROI Math

Affordability is more than a list price. A realistic comparison includes power draw, shielding gas, consumables, maintenance, training time, and the productivity gains your actual parts can support. Price tiers vary by region and configuration, but a practical snapshot looks like this:

– Entry handheld (about 1–1.5 kW): roughly $8,000–$18,000

– Mid-range handheld/benchtop (about 1.5–2 kW): roughly $15,000–$30,000

– Higher-power or integrator-grade (about 2–3 kW+): roughly $28,000–$60,000

Wall-plug efficiency for fiber sources commonly lands in the 30–40% range. A 1.5 kW optical output may draw in the ballpark of 4–5 kW from the wall under load, depending on optics and duty cycle. If your electricity rate is $0.15/kWh and the system averages 4.5 kW during welding, you’re near $0.68 per hour in electricity. Shielding gas is frequently the next significant line; at 12 L/min and a delivered cost equivalent to $0.30–$0.80 per cubic meter, gas can add roughly $0.22–$0.58 per hour. Consumables include nozzles, ceramic tips, protective windows, and occasional optics cleaning kits; budgeting a few dollars per operating hour is realistic for many shops, higher if wire feed is used heavily.

Now to value. Let’s imagine you weld 1 mm stainless lap joints totaling 200 meters per week. If a conventional process runs at 0.4 m/min with substantial post-grind time and the laser can hold 1.6 m/min with minimal cleanup, you could see a 3–4x throughput increase on the weld pass and a notable drop in rework. Even after accounting for training and occasional parameter development, labor hours fall. If a machine saves two technician-hours per day at $35/hour burdened cost, that’s about $16,800 per year in time alone (assuming 240 workdays). Add reduced abrasives and rework costs, and many shops find payback in months rather than years—provided their parts, schedules, and upstream prep support repeatable laser welding.

Hidden costs to anticipate:

– Training: A day or two to learn torch angles, travel speed, and parameter tweaks can prevent scrap.

– Safety: Laser-rated eyewear, interlocks, curtains, and fume extraction are essential for Class 4 systems.

– Fixturing: Simple clamps often suffice, but dedicated fixtures pay off for repeat runs.

– Downtime: Keep spare tips, nozzles, and windows on hand to avoid stoppages.

Bottom line: an affordable machine earns its keep when it aligns with your real workload. Build a simple spreadsheet with weld lengths, time per meter, scrap rate, and finishing hours, then pressure-test the numbers in a short pilot before fully committing.

Applications and Materials: Where Lasers Excel and What to Watch

Laser welding thrives on clean, consistent joints and rewards good part prep with fast, tidy seams. Stainless steel is a common winner: thin sheet cabinets, frames, enclosures, and food-grade components often show smaller heat-affected zones and less finishing than conventional processes. Mild steel performs similarly, while aluminum is entirely feasible with careful cleaning and parameter control. Copper and brass are possible, but reflectivity and thermal conductivity raise the difficulty, pushing settings toward higher peak power, slower travel, or pulsed techniques.

Typical ranges seen in practice (always verify on your parts):

– Stainless and mild steel: 0.5–4 mm for handheld units around 1.5–2 kW; thicker sections demand power and fixturing.

– Aluminum: 1–3 mm is common; critical to remove oxide and oils to avoid porosity.

– Copper and brass: target pulsed or higher power, meticulous surface prep, and tight process control.

Joint types include butt, lap, and fillet. Butt joints need accurate fit-up; lasers can struggle with wide gaps without filler. Lap joints are forgiving and popular for thin sheet. Fillets benefit from wire feed if leg size or aesthetics matter. Wobble patterns help span small gaps and reduce sensitivity to travel alignment, trading some speed for robustness. Shielding gas choice influences bead color and porosity; nitrogen can be attractive on certain stainless grades for cost and speed, while argon remains a reliable default for appearance and stability.

Common pitfalls and how to counter them:

– Porosity: Clean thoroughly, optimize gas flow (avoid turbulence), tweak power and speed to stabilize the keyhole.

– Lack of fusion: Increase power or reduce speed; adjust focus position to put energy where it’s needed.

– Undercut or excessive concavity: Lower power density, widen wobble, or add wire for profile support.

– Spatter: Tame with better fit-up, stable parameters, wire feed tuning, or a slight angle adjustment.

Quality verification shouldn’t be an afterthought. Simple macro-etches on cross-sections quickly reveal penetration and fusion. Bend tests expose lack of fusion or brittle zones. Track parameters alongside results so you can return to proven recipes. Over time, you’ll build a library of settings tied to material, thickness, and joint design—an asset as valuable as the machine itself, especially when new team members join the line.

Buying Checklist, Safety, Setup Tips, and Conclusion

Before you spend a dollar, translate your parts list into machine requirements. Note materials, thicknesses, joint types, and desired travel speeds. Decide whether you need filler wire, a wobble head, or automation paths down the road. Then weigh power, duty cycle, and ergonomics against real workspace constraints and the skills of your operators. A short demo or rental trial with your parts is often worth more than a stack of spec sheets.

Practical buying checklist:

– Power and optics: Can it meet your thickest joint with acceptable speed and quality?

– Wobble and presets: Useful for gap bridging and quick recipe changes between jobs.

– Wire feed: Essential if fit-up varies or if you need specific bead profiles.

– Controls and memory: Store, recall, and lock recipes to reduce variability.

– Safety systems: Interlocks, key switch, and clear Class 4 labeling; curtains or enclosures for the work area.

– Service and parts: Availability of consumables, windows, nozzles, and prompt technical support.

– Electrical and gas: Verify circuit capacity and stable gas supply at 10–20 L/min for typical work.

Safety is non-negotiable. Class 4 lasers require controlled areas, appropriate eyewear with the correct optical density at the operating wavelength, and thoughtful beam management. Fume extraction is important; welding fumes and metal vapors don’t belong in lungs or optics. Reference widely adopted standards such as IEC 60825-1 for laser safety and ANSI Z136.1 for safe use of lasers, and follow national regulations for ventilation and personal protective equipment. A short safety briefing, clear signage, and disciplined housekeeping go a long way toward keeping the process predictable.

Setup notes for smooth starts:

– Electrical: Handheld units often run on single- or three-phase; confirm voltage and breaker sizing.

– Grounding: A clean work clamp connection reduces spatter and stabilizes the arc plume dynamics.

– Optics care: Keep protective windows clean; stash spares to avoid downtime mid-run.

– Parameter logs: Record material, thickness, gas, power, speed, wobble, and results; this builds a recipe playbook.

Conclusion for buyers: Affordable laser welding can be a high-impact upgrade when matched to the right parts and processes. Prioritize the work you actually do, test on representative joints, and calculate total cost of ownership—not just sticker price. If your jobs favor thin to mid-gauge metals and you value neat seams with minimal finishing, a well-chosen, well-regarded laser welder can elevate throughput and consistency without overextending your budget. Start small, validate quickly, and scale with confidence.