Interested in becoming an electrician? Check out our learning guide!

Outline and Learning Path at a Glance

Before you lift a screwdriver or trace a circuit, a clear learning path helps you avoid detours and frustration. Here’s the map you’ll follow in this guide, first as an outline and then expanded in depth. The sequence mirrors how successful training programs scaffold skills: theory that explains what’s happening inside the wires, hands-on practice that makes those ideas stick, and credentials that convert your effort into employability. While different schools, trade centers, and apprenticeship providers arrange modules in their own way, the following structure reliably builds skill from the ground up.

– Foundations: math refresh (ratios, powers, basic algebra), physics intuition (current, voltage, energy), and safety principles you’ll use daily

– DC circuits: components, Ohm’s law in action, series/parallel behavior, measurement basics

– AC power: frequency, phasors explained simply, power factor, single-phase vs. three-phase systems

– Equipment: transformers, motors, variable-speed concepts, protection and grounding

– Tools and testing: safe use of multimeters, clamp meters, continuity tests, insulation checks

– Wiring methods: residential, commercial, and light industrial practices; conduit, cable, and terminations

– Codes and compliance: reading and applying electrical codes, permits, and inspection readiness

– Controls: contactors, relays, overloads, and an entry point to programmable logic concepts

– Drawings: diagram reading, panel schedules, and as-built documentation

– Projects and troubleshooting: capstone build, systematic fault-finding, and documentation habits

– Career prep: credentials, exam prep, portfolio building, and interview readiness

Time planning matters as much as content. A focused starter plan might look like twelve weeks part-time, with two evenings for theory (about four to six hours) and one longer weekend lab (three to five hours). You can stretch that to twenty-four weeks if your schedule is tight, or compress it with a full-time boot-camp format if you can step away from other commitments. Layer practice into your week: short daily drills with measurements, thirty-minute code reading sessions, and one deeper weekend project block. Milestones keep momentum: complete DC labs by week four, master fundamental AC and safety testing by week eight, and finish a small control panel or lighting circuit by week twelve. Keep a skills log that notes what you did, what worked, and what you’ll improve next; portfolios that show measured results, annotated photos, and wiring diagrams help employers see your judgment, not just your enthusiasm.

Core Electrical Theory: From Ohm’s Law to Power Systems

Solid theory is a practical tool, not abstract trivia. Start with the basics: voltage pushes, current flows, resistance pushes back, and power is the rate at which work is done. Apply that in everyday terms: if a 1200-watt heater runs on a 120-volt circuit, expect roughly 10 amperes of current; that back-of-the-envelope estimate immediately tells you whether the breaker size and wire gauge are appropriate. Series and parallel behavior matter for safety and performance—add loads in series and you increase total resistance, add them in parallel and total resistance drops as more pathways open. Kirchhoff’s laws—summing voltages around a loop and currents at a node—let you sanity-check your readings during troubleshooting.

Alternating current introduces timing and angles without requiring heavy math. Most grids operate at either 50 or 60 cycles per second, and that rhythm shapes how inductors and capacitors behave. Inductors resist changes in current, while capacitors resist changes in voltage; together they influence a circuit’s power factor, the ratio between useful power and total power drawn. In real jobs, poor power factor can make equipment run hotter and raise energy costs; adding capacitive correction on the right side of a motor circuit can bring the ratio closer to unity and ease the strain. Three-phase systems distribute power smoothly and efficiently; you’ll meet them in commercial spaces and industrial rooms where motors and large HVAC units live. Even a simple model—seeing three sine waves offset like a three-piece dance—helps you predict currents and plan conductor sizes.

Transformers quietly enable safe, efficient distribution by stepping voltages up or down with magnetic coupling, and they do it with striking reliability when sized and protected correctly. Rectification and filtering bridge the gap between AC supply and DC electronics, making lighting controls, sensors, and small automation possible. As you read course outlines, look for modules that connect theory to measurements: measuring voltage drop under load to validate a wiring run, comparing nameplate current to your clamp readings on a motor start, or checking insulation resistance before energizing a new segment. When theory regularly answers “what should I expect to see?” you’ll find that troubleshooting becomes faster, calmer, and far more accurate.

Hands-On Skills and Labs: Wiring, Safety, and Tools

Hands-on training turns concepts into muscle memory and safe habits. The first lab skill is not a cut or a measurement; it’s risk assessment. Get used to a quick checklist before any task: identify the energy sources, verify isolation with proper lockout and tagout, test for absence of voltage with a meter you’ve just proven on a known live source, and only then begin work. Protective equipment—gloves rated for the task, safety glasses, and appropriate footwear—keeps small mistakes from becoming setbacks. Treat every panel or junction as if it could surprise you until your tests prove otherwise.

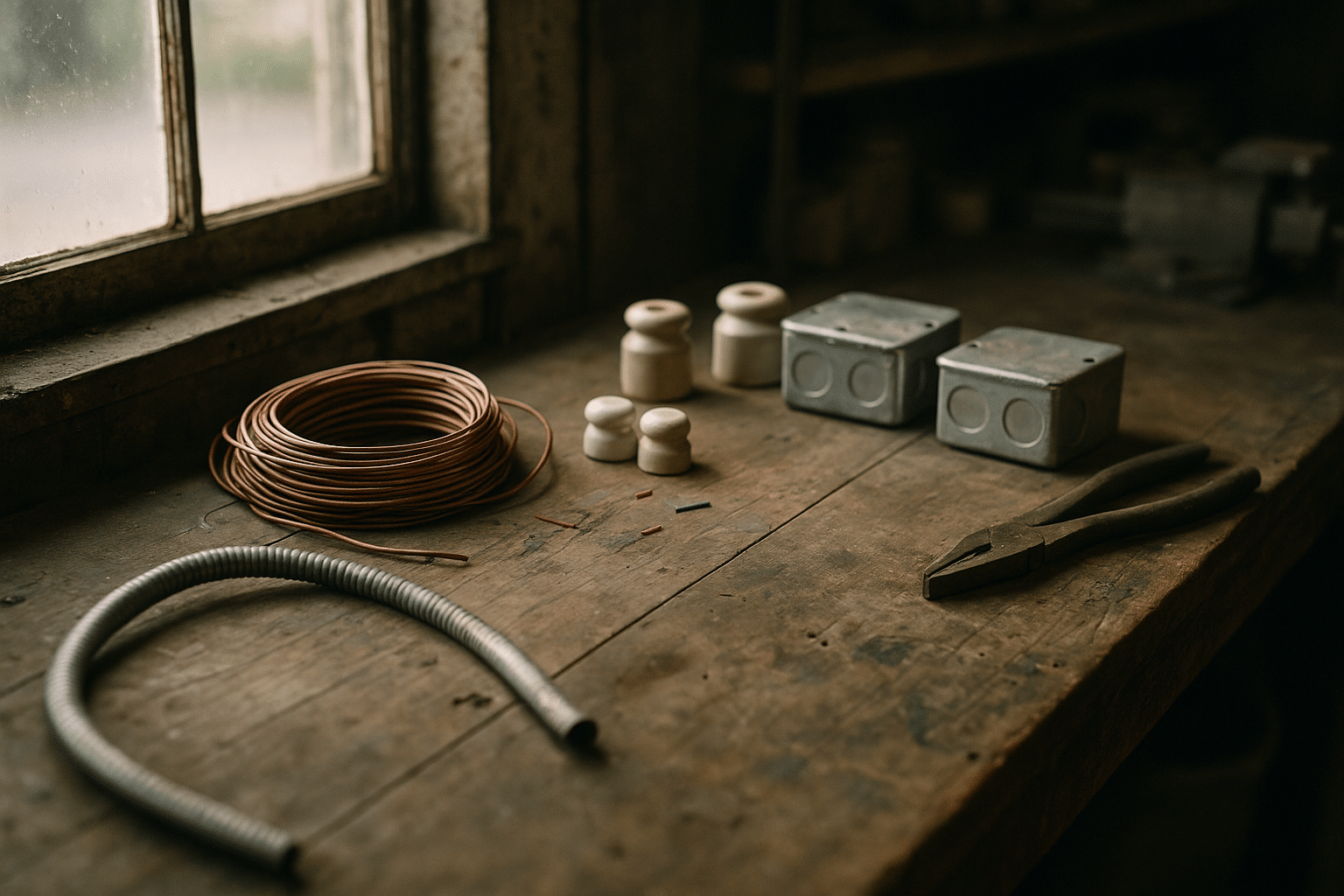

Tool familiarity builds confidence. A multimeter and clamp meter are the daily drivers: measure voltage, current, and resistance without guesswork, and log readings so you can compare them later. A non-contact tester helps with quick screening, though it never replaces a proper meter. Wire strippers, crimpers, torque screwdrivers, and conduit benders round out your basics. Keep blades sharp, leads intact, and meters calibrated on schedule. Organize your kit so you can perform a shutdown, verify de-energization, perform work, and re-energize in a repeatable sequence—consistency prevents errors when fatigue sets in.

Wiring methods vary by environment. Residential spaces use cable assemblies and plastic boxes; commercial sites lean on metal conduit, busways, and larger panels; light industrial settings add motor feeders, control cabinets, and more robust protection. Practice neat routing, appropriate bend radii, and secure terminations that meet torque specs. Match conductor size to current and distance to avoid excessive voltage drop; if a long run serves a motor and your calculations show a drop that could impair starts, upsize the conductor preemptively. Color conventions guide identification; follow local rules faithfully to make future maintenance safer. Common lab steps that courses should include are these:

– Terminate a branch circuit with a receptacle and a switch controlling a lamp holder

– Pull conductors through a short conduit run, ensuring fill and bend rules are respected

– Install and test a ground fault protective device, then document trip behavior

– Wire a small motor starter with an overload relay and a start/stop station

– Perform insulation resistance tests on a new run and compare to expected thresholds

Troubleshooting ties it all together. Start with the symptom, review the last change made, and follow the energy path. Measure, don’t assume; a continuity test and a careful visual inspection solve many issues faster than swapping parts. Write down your steps, because a calm record is precious when a supervisor asks what you did under time pressure. Good labs teach you to slow down before you can speed up.

Course Formats and Credentials: Certificates, Diplomas, and Degrees

Courses come in several shapes, and the right one depends on your timeline, budget, and career goals. Short certificates focus on immediate skills: safety, basic DC and AC, essential tools, and entry-level wiring. Expect eight to sixteen weeks part-time, often designed so you can keep working while you learn. Diplomas (or longer certificates) stretch to several months and add controls, code navigation, and more involved projects; these programs create a solid bridge into apprenticeships. Associate-level study typically spans two years and layers in deeper electronics, power systems, drafting, and math; it suits learners who want broader credentials and the option to pivot into design or maintenance planning later. Full degrees in electrical engineering emphasize advanced theory, calculus-based analysis, and design; they open routes into design offices, utilities, and product development, while still supporting hands-on understanding if labs are emphasized.

Delivery format matters. In-person labs are hard to replace; bending conduit, landing conductors, and proving out circuits builds confidence you can’t get from slides. That said, blended options can be efficient: theory modules online with evening or weekend labs at a training workshop. When comparing programs, prioritize those that require you to measure, document, and defend your lab results; graded lab notebooks and practical checkouts are strong signals of quality. Look for structured feedback, not just attendance grades.

Budgeting helps you commit. Short programs may cost from a few hundred to a few thousand in tuition depending on region and equipment access; multi-term study can reach higher totals, but often includes lab materials, exam prep sessions, and instructor office hours. Many learners stack funding: employer reimbursement, small scholarships, or payment plans that spread the load. Time is another currency: a part-time certificate might ask six to ten hours per week, while immersive formats can run thirty or more. You’ll also invest in a basic tool kit; most programs list a minimal set so you can start lean and add as you go. For credibility, confirm that the curriculum aligns with local licensing requirements and that hours can count toward apprenticeship or continuing education where applicable. A credential that helps you pass an exam and perform safely on day one is the one that earns its place on your resume.

Conclusion and Next Steps for Aspiring Electricians

You now have a clear picture of how electrical engineering courses connect to real, paid work: theory builds judgment, labs create safe habits, and credentials open doors. The next move is about momentum. Choose a format that fits your life and mark the calendar with protected study blocks. Commit to a modest, steady cadence rather than heroic bursts; consistency beats intensity when you’re building a trade. Start a learning journal on day one, and add photos of your lab setups, recorded measurements, and short reflections on what you would do differently next time. Employers value evidence of thinking as much as finished work.

Use a simple 30-60-90 plan to stay focused:

– Days 1–30: finish a math and safety refresh, complete DC labs, and set up your tool kit

– Days 31–60: tackle AC topics, practice systematic testing, and wire two small projects end to end

– Days 61–90: build a compact control circuit, rehearse troubleshooting under a timer, and rehearse exam-style questions

Network modestly and purposefully. Visit local supply houses during slower hours and ask about common mistakes they see in new installers. Attend an open lab night or community event hosted by a training provider and politely ask instructors what separates reliable apprentices from the rest. Build a portfolio that shows progression, not just highlights: early attempts, corrections you made, and final results with measured data. Soft skills matter too—clear notes, tidy work areas, and on-time communication make technical strengths visible.

Finally, stay humble and curious. Codes and technologies evolve, and a good electrician evolves with them. Set a reminder every quarter to learn one new topic—maybe grounding nuances, variable-frequency drives, or energy-efficient lighting controls—and add it to your portfolio with a small demo. That habit transforms courses into a career. Get your plan on paper today, enroll in a course that aligns with your goals, and start building the competence that makes your work safer, quicker, and trusted.