Laser welding equipment: Advancements in Precision and Efficiency for Industrial Applications

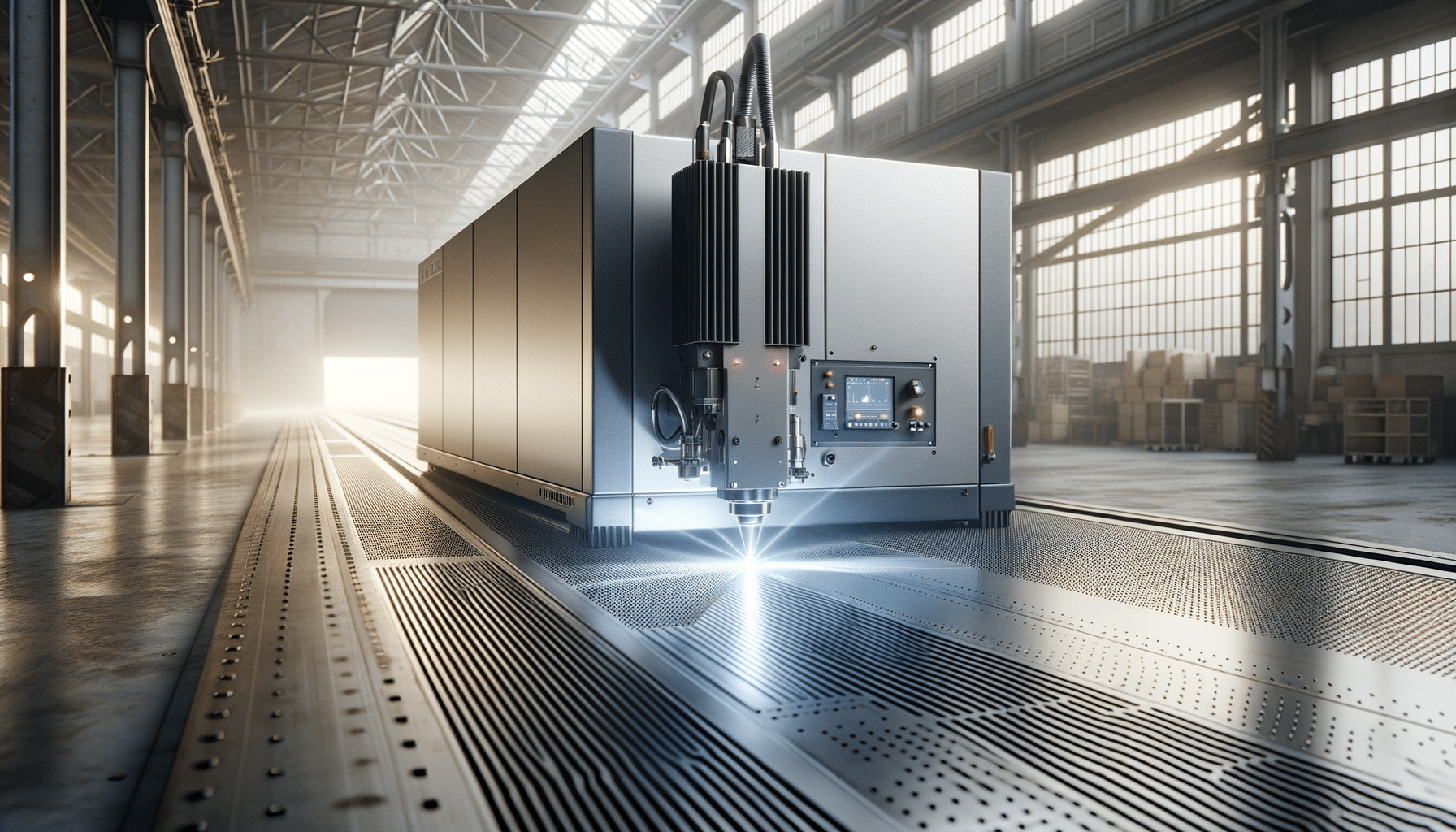

Introduction to Laser Welding Machines

Laser welding machines have become an essential tool in modern manufacturing, offering precision and efficiency that traditional welding methods struggle to match. This article explores the various advantages of laser welding machines, particularly focusing on their impact on manufacturing processes. We will delve into the technology’s benefits, the rise of portable models, pricing considerations, and how these advancements are reshaping industrial applications.

The Advantages of Laser Welding Machines

Laser welding machines offer several key advantages that make them a preferred choice in many industrial applications. One of the primary benefits is their ability to provide exceptional quality welds with minimal distortion. The precision of laser welding allows for highly accurate joints, which is critical in industries where tolerance levels are stringent. Additionally, laser welding offers a non-contact process, reducing the wear and tear on equipment and extending its lifespan.

Another significant advantage is the speed at which laser welding can be performed. This efficiency not only reduces production time but also lowers overall costs. The ability to automate laser welding processes further enhances productivity, making it an attractive option for high-volume manufacturing. Moreover, laser welding machines are versatile, capable of working with a wide range of materials, including metals and plastics, which broadens their applicability across various sectors.

- Precision and accuracy in welds

- Non-contact process reduces equipment wear

- High-speed operation enhances productivity

- Versatile material compatibility

The Rise of Portable Laser Welding Models

In recent years, the development of portable laser welding models has revolutionized the industry, providing flexibility and convenience previously unattainable with traditional systems. These portable models are particularly beneficial for on-site repairs and maintenance, where transporting large equipment would be impractical. With compact designs and user-friendly interfaces, portable laser welders offer an excellent solution for industries such as automotive, aerospace, and construction, where mobility is crucial.

Despite their smaller size, portable laser welders do not compromise on power or precision. They are equipped with advanced features that enable high-quality welds in challenging environments. As these models continue to evolve, they are becoming more accessible to smaller businesses, enabling them to leverage the advantages of laser welding without the need for significant capital investment.

- Enhanced mobility for on-site applications

- Compact design without sacrificing power

- User-friendly interfaces for ease of use

- Cost-effective solutions for small businesses

Pricing Considerations for Laser Welding Machines

When considering the adoption of laser welding technology, understanding the pricing dynamics is essential. The cost of laser welding machines can vary significantly based on factors such as power output, features, and brand reputation. High-end models with advanced capabilities are typically more expensive, but they offer greater efficiency and versatility, which can justify the initial investment over time.

It’s important for businesses to evaluate their specific needs and assess the long-term benefits of investing in laser welding technology. The reduction in production time and improvement in product quality can lead to substantial cost savings, making laser welding a financially sound decision in the long run. Additionally, as technology advances, the cost of laser welding machines is gradually decreasing, making them more accessible to a wider range of industries.

- Varied pricing based on power and features

- Long-term cost savings through efficiency improvements

- Increasing affordability with technological advancements

Impact on Manufacturing Processes

The integration of laser welding machines into manufacturing processes has brought about significant improvements in efficiency and product quality. By enabling precise and consistent welds, laser welding reduces the need for secondary operations such as grinding or polishing, further streamlining production lines. This efficiency not only enhances throughput but also minimizes waste, aligning with sustainable manufacturing practices.

Furthermore, laser welding technology supports innovation in product design. The ability to join dissimilar materials and create complex geometries opens up new possibilities for manufacturers, allowing them to develop products that were previously not feasible. As industries continue to embrace laser welding, it is clear that this technology is playing a crucial role in driving the evolution of manufacturing practices.

- Streamlined production with reduced secondary operations

- Minimized waste through precise and consistent welds

- Facilitates innovative product design

- Supports sustainable manufacturing practices

Conclusion

In conclusion, laser welding machines represent a significant advancement in manufacturing technology, offering numerous advantages that enhance productivity, precision, and versatility. The advent of portable models has further expanded the reach of laser welding, making it accessible to a broader range of industries. While pricing considerations are important, the long-term benefits of adopting laser welding technology are clear, with improvements in efficiency and product quality driving positive outcomes for manufacturers. As the technology continues to evolve, laser welding is set to play an increasingly vital role in shaping the future of industrial processes.