Laser welding equipment: Advancements in Precision and Efficiency for Industrial Applications

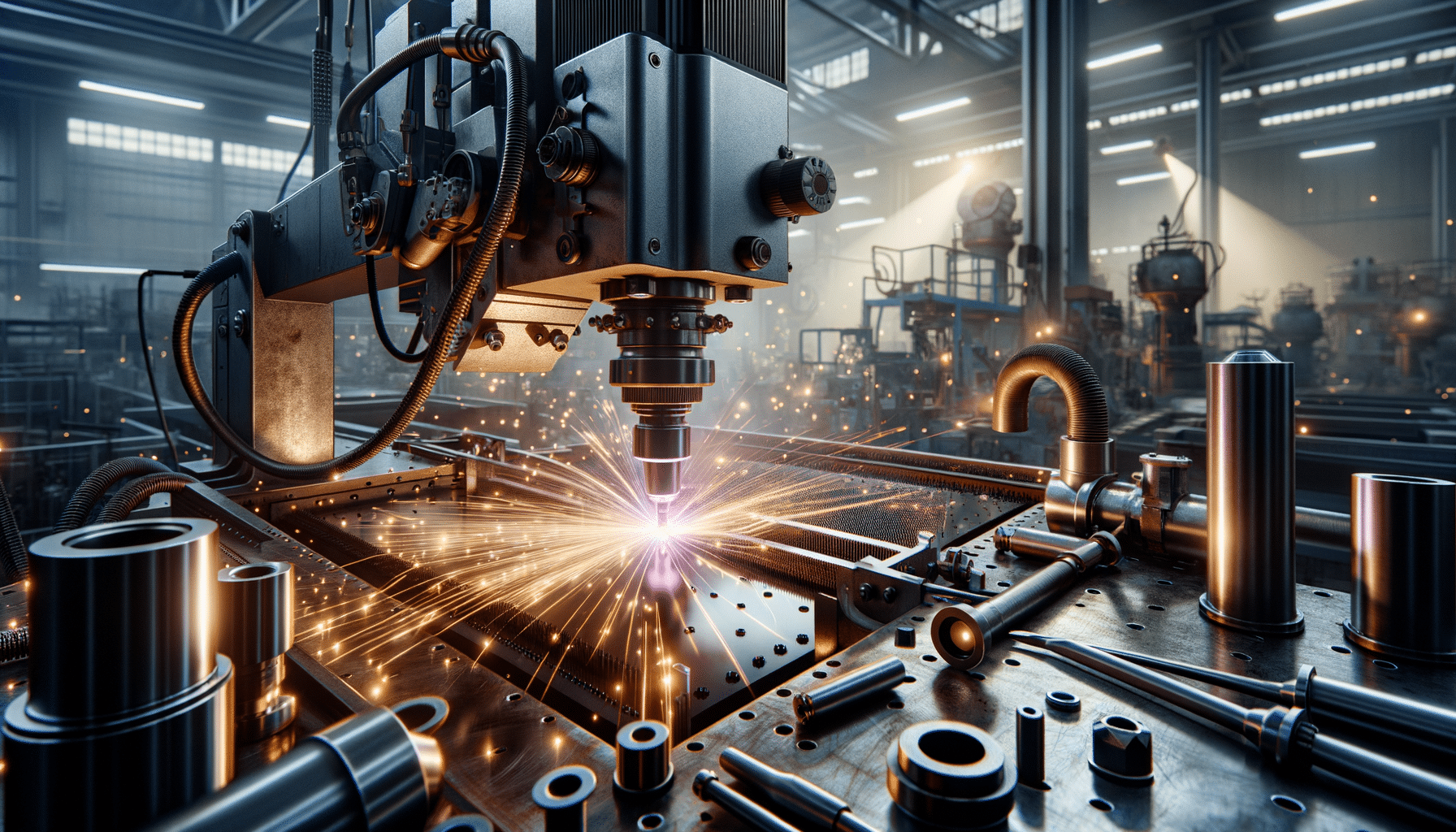

Introduction to Laser Welding Equipment

In the ever-evolving landscape of industrial manufacturing, laser welding equipment has emerged as a pivotal technology. Known for its precision and efficiency, laser welding offers numerous advantages over traditional welding methods. This article delves into the various aspects of laser welding equipment, exploring its significance, applications, and technological advancements.

Laser welding is a fusion welding process that employs a laser beam to join materials, usually metals or thermoplastics. This technology is renowned for its ability to create high-quality welds with minimal heat input, reducing distortion and allowing for intricate designs. As industries strive for greater efficiency and precision, laser welding equipment has become an essential tool in sectors such as automotive, aerospace, and electronics.

Advantages of Laser Welding Machines

One of the primary benefits of laser welding machines is their precision. The focused laser beam allows for exceptional control over the welding process, resulting in clean and accurate welds. This precision is particularly advantageous in industries requiring high-quality finishes and complex geometries.

Additionally, laser welding machines offer remarkable speed. The rapid heating and cooling cycles enable faster production rates compared to conventional welding methods. This efficiency not only boosts productivity but also reduces operational costs, making it a cost-effective solution for manufacturers.

Another significant advantage is the ability to weld a wide range of materials. Laser welding is compatible with various metals, including steel, aluminum, and titanium, as well as non-metallic materials like plastics. This versatility allows manufacturers to tackle diverse projects with a single technology.

- Precision and accuracy

- High production speed

- Versatility in material compatibility

Exploring Portable Laser Welding Models

Portable laser welding models have gained popularity due to their flexibility and convenience. These compact units are designed for ease of transport and operation in various settings. Portable models are particularly useful in fieldwork, where stationary equipment may not be feasible.

Despite their smaller size, portable laser welders do not compromise on performance. They offer similar precision and efficiency as their larger counterparts, making them suitable for on-site repairs and maintenance tasks. Industries such as construction and shipbuilding benefit greatly from these portable solutions.

Moreover, the user-friendly interfaces of portable models ensure that operators can quickly learn and adapt to the technology, minimizing downtime and maximizing productivity. This ease of use, combined with their mobility, makes portable laser welding machines an attractive option for many businesses.

Understanding Pricing and Cost Considerations

The pricing of laser welding equipment can vary significantly based on factors such as power output, brand, and additional features. While the initial investment may be higher than traditional welding equipment, the long-term savings in operational costs often justify the expenditure.

When evaluating costs, it’s essential to consider the specific needs of your operation. Higher-powered machines typically command higher prices but offer greater capabilities and efficiency. Conversely, smaller, portable units may be more affordable while still meeting the demands of certain applications.

Additionally, manufacturers should factor in maintenance and training costs. Proper maintenance ensures the longevity and reliability of the equipment, while training enables operators to maximize the equipment’s potential. By carefully considering these aspects, businesses can make informed decisions that align with their financial and operational goals.

- Initial equipment cost

- Maintenance expenses

- Training investments

Conclusion: Impact on Manufacturing Processes

Laser welding equipment has undeniably transformed manufacturing processes across various industries. Its precision, speed, and versatility make it an invaluable tool for achieving high-quality results. As technology continues to advance, the capabilities of laser welding machines are likely to expand, opening new possibilities for innovation.

For businesses seeking to enhance their production capabilities, investing in laser welding equipment can provide a competitive edge. By leveraging the advantages of this technology, manufacturers can improve product quality, reduce costs, and increase efficiency, ultimately leading to greater success in the marketplace.

In conclusion, laser welding equipment represents a significant advancement in industrial technology, offering solutions that are both efficient and adaptable to the ever-changing demands of modern manufacturing.