Laser Welding Machines: Advancements in Precision

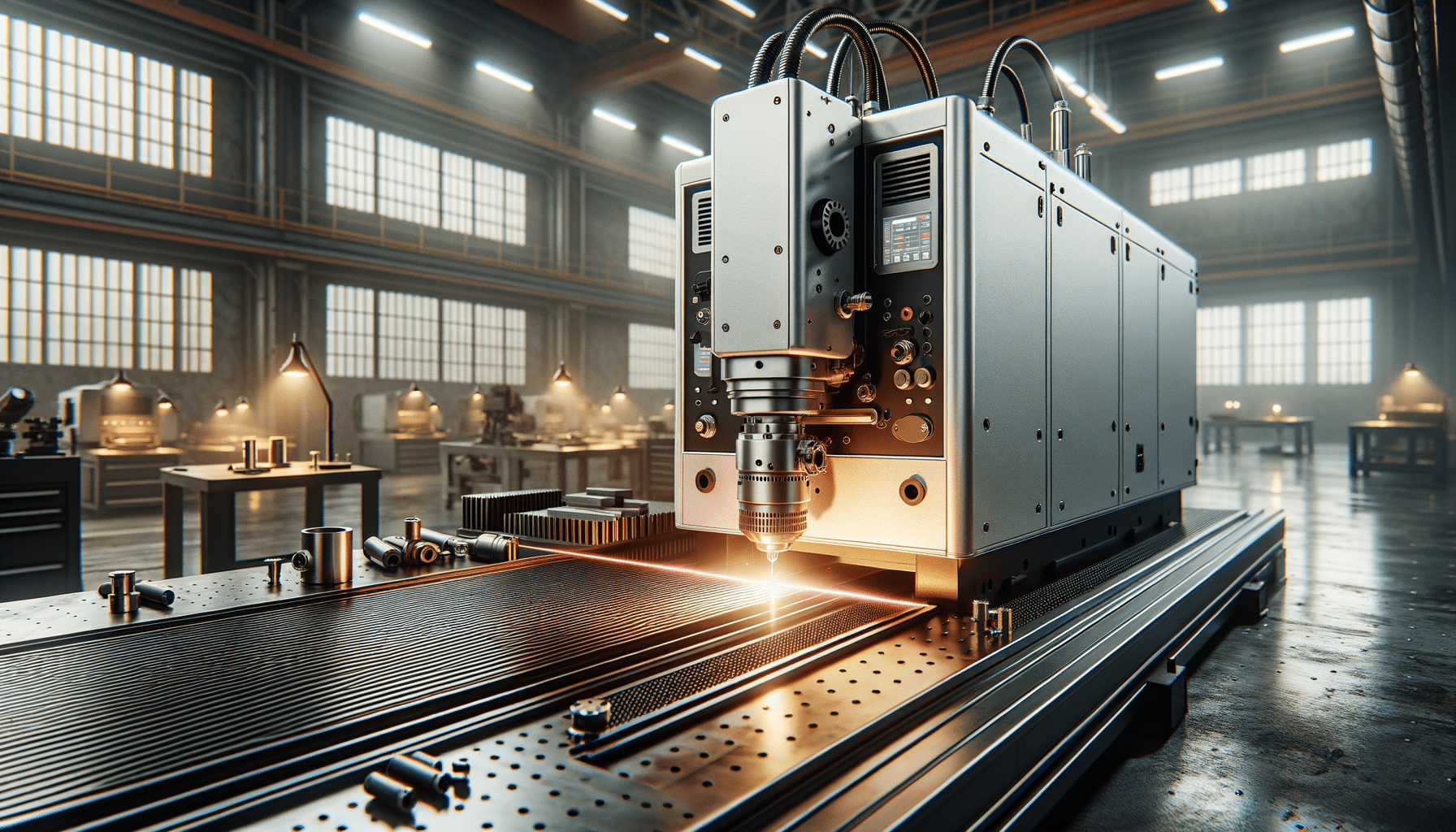

Introduction to Laser Welding Machines

In the realm of manufacturing and industrial applications, laser welding machines have emerged as a pivotal technology, enhancing precision and efficiency. These machines utilize a laser beam to join metal pieces, providing a high-quality weld that is both strong and aesthetically pleasing. As industries continue to demand higher standards of production, the relevance of laser welding machines grows, offering solutions that traditional welding methods struggle to match. In this article, we will delve into the various facets of laser welding machines, including their advantages, the rise of portable models, pricing considerations, and their overall impact on manufacturing processes.

Advantages of Laser Welding Machines

Laser welding machines offer several advantages over traditional welding techniques. One of the most significant benefits is their precision, which allows for highly accurate welds that are crucial in industries such as aerospace and automotive manufacturing. The focused laser beam minimizes heat input, reducing distortion and thermal damage to surrounding materials.

Another advantage is the speed of operation. Laser welding machines can complete welds much faster than conventional methods, increasing production rates and efficiency. This speed does not compromise quality, as the welds produced are consistent and reliable.

Moreover, laser welding is versatile, capable of joining a wide range of materials including metals, plastics, and even dissimilar materials. This adaptability makes it an invaluable tool in various sectors. Additionally, the non-contact nature of laser welding reduces wear and tear on machinery, leading to lower maintenance costs and longer equipment lifespan.

The Rise of Portable Laser Welding Machines

As technology advances, the development of portable laser welding machines has been a game-changer for many industries. These compact units offer the same precision and efficiency as their larger counterparts but with added flexibility. Portable models are particularly beneficial in settings where mobility and ease of access are crucial, such as on-site repairs and maintenance.

The portability of these machines does not compromise their power. They are designed to be user-friendly, often featuring intuitive interfaces and ergonomic designs to facilitate ease of use. This has opened up possibilities for small and medium-sized enterprises to adopt laser welding technology without the need for significant infrastructure investments.

Furthermore, portable laser welding machines have contributed to reducing downtime in production lines. Their ability to be swiftly deployed to different locations means that operations can continue with minimal disruption, enhancing overall productivity.

Pricing Considerations for Laser Welding Machines

Investing in laser welding machines involves several pricing considerations. Initially, the cost of these machines can be higher compared to traditional welding equipment. However, the long-term benefits often justify the investment, as laser welding machines contribute to higher efficiency and lower operational costs.

Factors influencing the pricing of laser welding machines include power output, level of automation, and additional features such as cooling systems and advanced control interfaces. While high-end models with extensive features may command a premium, there are also budget-friendly options that offer essential functionalities suitable for smaller operations.

To optimize investment, businesses should evaluate their specific needs and production requirements, ensuring they select a machine that aligns with their operational goals. Additionally, considering the total cost of ownership, including maintenance and operational efficiency, can provide a clearer picture of the machine’s value over time.

Impact on Manufacturing Processes

The integration of laser welding machines into manufacturing processes has significantly enhanced production capabilities. These machines offer unparalleled precision, which is vital for industries that require exacting standards, such as electronics and medical device manufacturing.

By reducing the need for post-weld processing, laser welding machines streamline manufacturing workflows, leading to faster turnaround times and reduced labor costs. The precision and reliability of the welds also enhance product quality, reducing the likelihood of defects and rework.

Moreover, the adoption of laser welding technology aligns with the growing emphasis on automation and Industry 4.0. These machines can be easily integrated into automated production lines, facilitating seamless operations and data-driven decision-making. As a result, manufacturers can achieve greater flexibility and responsiveness to market demands.

Conclusion: Embracing the Future with Laser Welding

Laser welding machines represent a significant advancement in manufacturing technology, offering precision, efficiency, and versatility. As industries continue to evolve, the adoption of laser welding will likely increase, driven by the demand for high-quality, reliable, and cost-effective production solutions. By understanding the advantages, exploring portable options, and considering pricing strategies, businesses can effectively integrate laser welding machines into their operations, positioning themselves for success in a competitive landscape.