Laser Welding Machines: Advancements in Precision

Introduction to Laser Welding Machines

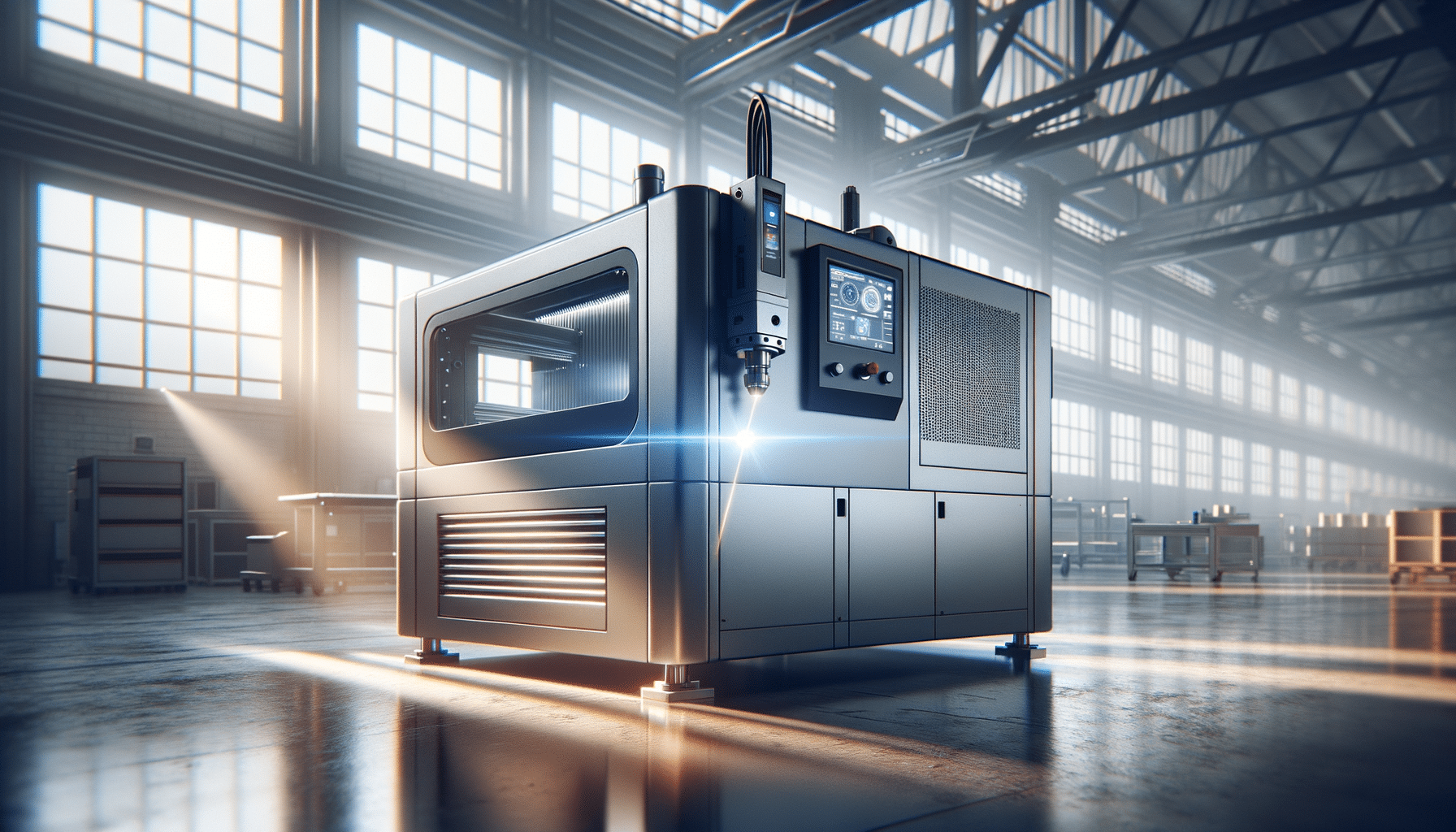

In the realm of modern manufacturing, laser welding machines have emerged as a pivotal technology, offering precision and efficiency that traditional welding methods struggle to match. The ability to produce high-quality welds with minimal distortion has made these machines indispensable across various industries. Their applications range from automotive to aerospace, and even in delicate fields like medical device manufacturing. As we delve into the mechanics and benefits of laser welding machines, we uncover how this technology is reshaping manufacturing processes globally.

How Laser Welding Machines Work

Laser welding machines operate by focusing a high-intensity laser beam on the materials to be joined. This concentrated energy source melts the material at the joint, allowing it to fuse seamlessly. The precision of the laser beam ensures minimal heat-affected zones, reducing the risk of material warping or distortion. This process is particularly advantageous for materials that are sensitive to thermal damage.

One of the remarkable features of laser welding machines is their adaptability. They can be configured to handle a wide range of materials, from metals like steel and aluminum to non-metals such as plastics. Moreover, the technology supports various welding techniques including keyhole and conduction welding, each suited for different applications and material thicknesses.

- Keyhole welding: Ideal for deep, narrow welds, often used in thick materials.

- Conduction welding: Suitable for shallow welds, providing a smooth finish for thin materials.

The versatility and precision of these machines make them a preferred choice in industries requiring high-quality and reliable welds.

The Rise of Portable Laser Welding Machines

The development of portable laser welding machines has further expanded the scope of laser welding technology. These compact units offer the flexibility of performing high-precision welding operations in diverse environments, including on-site repairs and installations where traditional welding setups would be impractical. The portability factor does not compromise on performance, as these machines are equipped with advanced features that ensure quality and efficiency.

Portable laser welding machines are particularly beneficial in industries such as construction and maintenance, where mobility and ease of use are crucial. Their lightweight design coupled with user-friendly interfaces allows technicians to perform complex welding tasks with minimal setup time.

The cost-effectiveness of these machines, along with their ability to reduce labor costs and downtime, makes them an attractive investment for businesses looking to enhance their operational capabilities without significant infrastructure changes.

Cost Considerations and Investment Returns

Investing in laser welding technology requires careful consideration of the initial costs versus the potential returns. Laser welding machines, whether stationary or portable, represent a significant capital expenditure. However, the long-term benefits often justify the investment. These machines offer unparalleled precision, reducing material waste and rework costs.

The efficiency of laser welding machines translates into faster production cycles and lower labor costs, as fewer operators are needed to achieve the same output compared to traditional welding methods. Additionally, the high-quality welds produced lead to fewer post-processing requirements, further enhancing productivity.

For businesses contemplating the switch to laser welding, evaluating the total cost of ownership, including maintenance and operational expenses, is crucial. The investment can lead to substantial savings and competitive advantages, especially in industries where precision and quality are paramount.

Future Trends and Technological Advancements

The future of laser welding machines is poised for exciting developments as technology continues to advance. Innovations in laser source technology, such as fiber lasers, are enhancing the efficiency and power of these machines, allowing for even more precise and rapid welding processes. Additionally, the integration of automation and robotics with laser welding systems is paving the way for fully automated production lines.

As industries increasingly demand sustainable and energy-efficient solutions, laser welding technology is also evolving to meet these needs. The ability to perform high-quality welds with minimal energy consumption and material waste aligns with the global push towards greener manufacturing practices.

In conclusion, laser welding machines are not just a tool but a transformative technology that is shaping the future of manufacturing. Their precision, efficiency, and adaptability make them an invaluable asset in a rapidly evolving industrial landscape.